New services for surface optimization and additive manufacturing

The Materials and Processes Department offers four new services to improve the adherence of machine parts and to prolong the lifetime of tools, offering their customers the whole development process from the first idea to the implementation of the ready-to-run system:

Laser surface structuring for better adherence

Laser radiation can be used to roughen surfaces and thus improve the adherence characteristics of machine parts.

Laser alloying

Using laser alloying, wear-resistant coatings can be placed on different materials. In this way, the lifetime of tools can be prolonged.

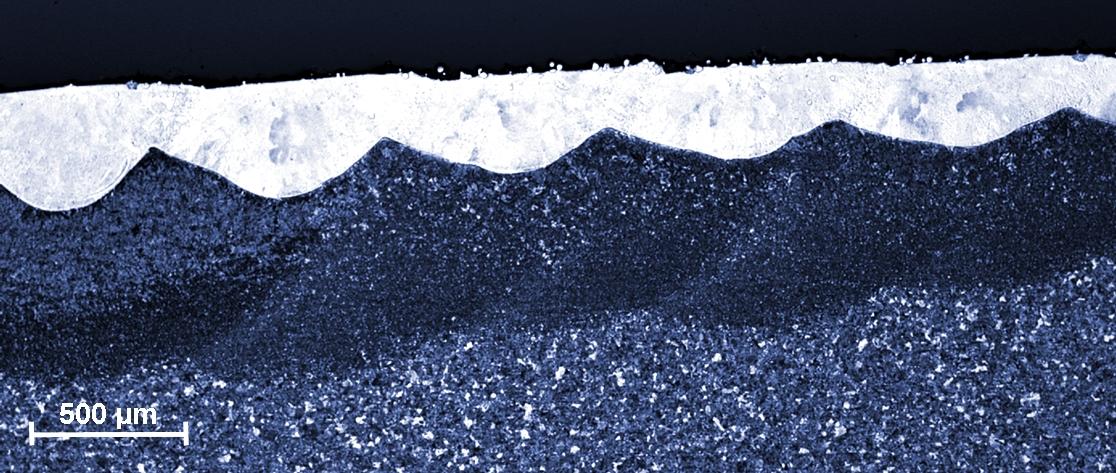

Laser dispersion

Using laser dispersion, metal-ceramic coatings can, for example, be added to moulding tools. These coating improve both the wear and corrosion characteristics of the tools, and can thus increase tool life.

Development of processing systems and system components

The Machines and Controls Group designs, constructs and makes processing systems and system components, mainly for deposition welding and surface technology. This also includes the necessary process development. From the idea to realization to implementation of the process system, the LZH experts accompany their customers through the whole development process.