Videos

Here is a selection of our videos. Do you have any questions? Our press contact will be happy to help.

Laser weeding

Put an end to the chemical club when it comes to weed control! A fully automated system drives over a field, a camera detects weeds, and a laser beam destroys the little villain. This future scenario was explored in a project at LZH. The main objective was non-chemical weed control, a key goal of ecological and sustainable crop production. A laser beam is used to hit the young weeds "with pinpoint accuracy" and spare the surrounding plants.

Laser versus weeds

Weeds and grass weeds are a common problem on agricultural land. To develop alternatives in the fight against weeds, grass weeds, and herbicide resistance, the Laser Zentrum Hannover e.V. is testing a laser-based approach for its practicality in the LURUU and NUBELA research projects. The aim is to specifically damage the growth center of the plant with laser radiation.

Light-based weed management

At LZH, we are researching automated, laser-based weed management. In this context, our own greenhouse allows us full control over the cultivation of plants, both for irradiation experiments and for the further development of AI plant recognition.

MOMA: Lasers search for traces of life on Mars

As part of the ExoMars 2020 mission, the European Space Agency (ESA) and the Russian space agency Roskosmos will send a rover to Mars. The aim of this mission is to actively search for former or current life on Mars. To this end, various scientific instruments are onboard the rover. The largest of these instruments is the Mars Organic Molecule Analyzer - MOMA.

MOONRISE: Bringing 3D-printing to the moon

Building villages on the moon out of lunar dust? In the MOONRISE project, LZH and the Institute of Space Systems (IRAS) at TU Braunschweig want to bring 3D printing to the moon. The goal of the MOONRISE project is to make lunar dust usable as a building material. Initial tests in HITec's Einstein Elevator were successful: The scientists succeeded in melting regolith into spheres under lunar conditions for the first time.

Monitoring the vegetation health with Alexandrite laser crystals

Laser-based instruments open up new ways to observe the atmosphere or the surface of planets. Space-qualified, high-power Alexandrite laser crystals with TRL 6 are important for future European Earth observation missions. This video explains how the EU's GALACTIC project will help monitor the effects of climate change from space.

Locating mineral resources in the deep sea with the laser

Bodenschätze am Meeresboden zu lokalisieren, ist bislang mit sehr hohen Kosten verbunden. Das Laser Zentrum Hannover e.V. (LZH) hat zusammen mit acht Partnern im EU-Projekt ROBUST ein laserbasiertes Analysesystem entwickelt, um Bodenproben in der Tiefsee nahezu zerstörungsfrei zu untersuchen. Das System zur laserinduzierten Plasmaspektroskopie (engl. laser-induced breakdown spectroscopy, LIBS) ermöglicht es, Materialproben nahezu zerstörungsfrei auf ihre atomare Zusammensetzung hin zu untersuchen. Das vom LZH entwickelte LIBS-System hielt bei Praxistests in der Tiefsee einem Druck von 400 bar erfolgreich stand.

Laser cutting under water

Underwater work is complex. Therefore, the Laser Zentrum Hannover e.V. (LZH) and the Institute of Materials Science at Leibniz Universität Hannover have developed a laser process to automatically cut sheet pilings underwater. However, if they are to be dismantled, divers have to disassemble them with a cutting torch. Typically, a diver manages to cut about 20 meters per day, which corresponds to a speed of 0.07 m/min. In the LuWaPro project, the LZH has developed a process in which a disk laser makes the cuts in the torch cut. As a result, the diver now only performs a control function.

A gentle laser cleaning system for use under water

Marine fouling on ship hulls is a significant problem for the industry. This so-called biofouling increases flow resistance and thus fuel consumption and emitted emissions. Therefore, the Laser Zentrum Hannover e.V. (LZH), Laserline GmbH, and the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research (IFAM) want to develop a laser-based cleaning process to gently and efficiently remove the fouling without damaging the underlying coating.

Presbyopia

Presbyopia - this problem is known to millions of people. In technical terminology, this phenomenon is called "presbyopia". At the LZH, studies were conducted in collaboration with Laserforum Köln e.V. that demonstrated an increase in the deformability of the lens.

Bone implants with shape memory alloy

Commercial implants inserted after bone fractures cannot change their properties after implantation. However, if a stiffer implant is needed later, surgical intervention has been necessary until now. The so-called "shape memory alloy", or FGL for short, provides a remedy.

Laser-assisted adhesive bonding of diamond cutting segments

Bonding instead of soldering: The "Cutting and Joining of Metals" and "Safety Technology" groups at the LZH are collaborating with the Remscheid Institute for Tool Research and Materials (IFW) to research a laser-based process for replacing diamond cutting segments.

Unlike soldering, the heat input in laser-assisted bonding is significantly lower. This results in less stress in the saw blade and thus less distortion. Ideally, this means that in the future, no further straightening and tensioning of the saw blade will be necessary before reuse.

Laser-assisted arc welding

Joining robustly and with high quality at high welding speeds is what laser-assisted arc welding makes possible. In the process developed by the Laser Zentrum Hannover e.V. (LZH), an arc welding process (MAG/MIG/WIG) is stabilized by a laser beam with low average output power. As a result, the laser-based process can increase the welding speed by 50 to 100 %. It is thus very cost- and energy-efficient compared to conventional welding.

Laser joining for glass and solar collectoren

Solar energy stands for an efficient and environmentally friendly energy supply. This system transforms solar energy into usable thermal energy. The LZH has researched a process for cost-optimization and improved production of solar collectors.

Laser repair of CFRP materials

Carbon fiber reinforced plastics (CFRP) exhibit high strength and stiffness while being very light. This makes this lightweight material the material of the future for the automotive and aerospace industries. But CFRP is a challenge for conventional manufacturing technology. Existing cutting processes, such as milling or waterjet cutting, result in very high tool wear or require water and abrasives. In the process, the cut edge can absorb moisture or be damaged by foreign particles.

Laser welding of thick metals sheets

By combining conventional processes with laser methods, material, work steps, and energy can be saved. For example, if MSG torches are combined with the laser, the latter additionally stabilizes the arc. As a result, the weld seam is significantly deeper, and the welding speed is increased. Particularly with thick plates, this can substantially reduce the welding time and the energy required.

We will demonstrate how heavy steel sheets up to 20 mm thick and aluminum up to 12 mm thick can be welded on one side. The process can be used with standard practical gap and tolerance dimensions.

Laser welding of metal-foam sandwiches

LZH researchers have developed a process for laser welding large-format metal foam sandwiches in a joint project. Metal foams are highly porous, lightweight materials that, due to their cellular structure, excellently dampen energy in the form of vibrations, impacts, or sound. In addition, they are temperature-resistant and simultaneously shield electromagnetic waves. In so-called sandwich constructions, i.e. in combination with aluminum or steel sheets, metal foams show a much higher bending stiffness than solid sheets and, due to their low weight, are particularly suitable for lightweight constructions as well as parts subject to high dynamic loads.

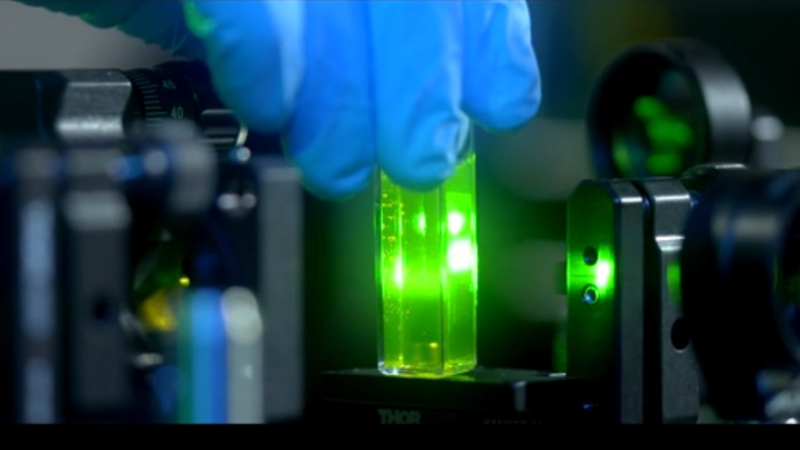

Laser-based nano-particle generation

Nanoparticles are particles that are over a thousand times smaller than the diameter of a human hair. They are used to produce scratch-resistant car paints or as protection against UV rays in sun creams. They can also do amazing things in medical technology. The LZH uses laser technology to produce nanoparticles.

Defusing unexploded bombs using the laser

Solar energy stands for efficient and environmentally friendly energy supply. In this process, solar energy is converted into usable heat energy. The LZH has researched a process to optimize costs and improve the production of solar collectors.

Can cells be activated and deactivated with a light switch? The research discipline of optogenetics deals with the effect of light on biological functions. In the Hannover Science Initiative video, Dr. Dag Heinemann and Dr. Sonja Johannsmeier from the LZH explain what optogenetics is and what potential it offers for many other research areas. (external link to wissen.hannover.de)