MOONRISE: LZH and TU Berlin bring 3D printing to the Moon with laser and AI

Joint press release of the Laser Zentrum Hannover e.V. (LZH) and the

Technische Universität (TU) Berlin

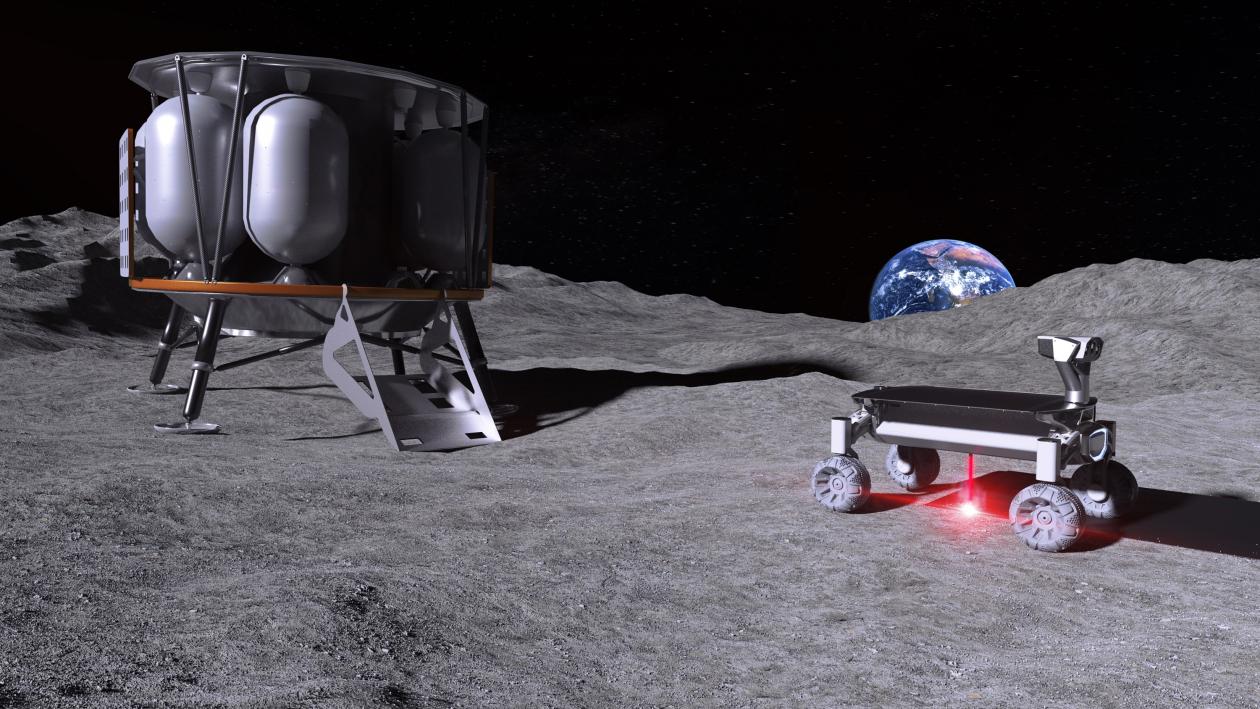

In the MOONRISE project, the research team wants to explore the question of how we can use lasers to build landing sites, roads or buildings out of lunar dust in the future. To do this, the researchers want to bring a laser system to the lunar surface and melt the lunar dust, a material that is available everywhere on the Moon. Artificial intelligence will support the laser process. The goal is to show that laser melting works on the moon – and, in perspective, can be used to produce 3D-printed infrastructure for a lunar base.

"At a cost of up to a million dollars per kilogram, a complete transport of the material from Earth to the Moon would be extremely expensive."

From both a scientific and an economic perspective, our terrestrial satellite is a coveted target. Billionaires are not the only ones who want to fly well-paying guests around the Moon; the European Space Agency (ESA) also has plans for a "Moon Village". This is because the far side of the Moon, which is always turned away from the Earth, would be suitable for powerful space telescopes. In addition, the lower gravity and lack of an atmosphere make the Moon an ideal stopover for setting up missions to more distant destinations in space. But how will launch pads, landing sites and buildings be constructed on the lunar surface? "At a cost of up to a million dollars per kilogram, a complete transport of the material from Earth to the Moon would be extremely expensive," explains Jörg Neumann, MOONRISE project manager at LZH.

Houses made of lunar dust

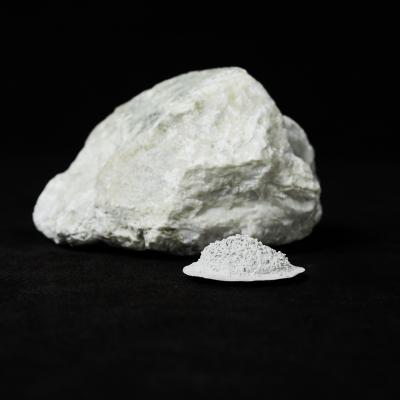

Pulverized lunar rock, or regolith, on the other hand, is abundant on the Moon and could be used as a raw material for 3D printing. On-site fabrication of infrastructure could save enormous transportation costs. The use and processing of on-site materials – also known as In-Situ Resource Utilization (ISRU) in spaceflight – could be a crucial factor in advancing the exploration of the Moon and space.

The technology has already been demonstrated on Earth

The groundwork for the project has already been laid. In the predecessor project funded by the Volkswagen Foundation, the research team developed a compact, robust laser and successfully tested it in the laboratory on the robotic arm of a lunar rover. The scientists also succeeded in melting regolith under lunar gravity in the Einstein-Elevator of the HiTEC (Hannover Institute of Technology) at Leibniz Universität Hannover.

The task now is to make the laser fit for lunar flight: The scientists from LZH and TU Berlin want to develop a flight model of the laser that is qualified for use in space.

Artificial intelligence for use on the Moon

The laser will be supported by artificial intelligence (AI). A camera will take photos on the Moon. Researchers on Earth will then analyze these photos with the help of an intelligent image processing system. The system will help analyze the lunar dust melted by the laser and provide the scientists on Earth with AI-based process and quality control.

"Our regolith construction kit will be adapted to the landing site on the Moon, so that in the laboratory the laser and the AI can be aligned with the real lunar mission."

Lunar Landscape at the TU Berlin

The big challenge here is that the AI must be trained in advance for use on the Moon. Therefore, scientists will create a laboratory at the TU Berlin in which they will photograph the regolith under lighting conditions that mimic those on the Moon. This will allow a corresponding pool of images to be created with which the AI can be trained. "In addition, a regolith construction kit has been developed over the past few years, which allows the various possible landing sites to be precisely recreated in terms of properties. This is then adapted in the project to the final landing site on the Moon, so that in the laboratory the laser and the AI can be aligned with the real lunar mission," explains Benedict Grefen from the group "Exploration and Propulsion" from the institute of Aeronautics and Astronautics (RFT) at TU Berlin. The "surface analog model" created in this way will then also support decision-making during the mission.

Flight to the Moon in 2024

The MOONRISE FM project will run for three years and is funded by the German Federal Ministry of Economics and Climate Action with 4.75 million euros. The mission is scheduled to launch in 2024.

About project MOONRISE

The MOONRISE FM project will test mobile selective laser melting of regolith on the lunar surface using artificial intelligence. Project partners are the Laser Zentrum Hannover e.V. and the Institute of Aeronautics and Astronautics at the TU Berlin. The project will run for three years and is funded by the German Federal Ministry for Economic Affairs and Climate Action under the funding code 50WP2206A. The project executing agency is the German Aerospace Center (DLR).

Please find all informationen about MOONRISE and previous experiments in the Einstein-Elevator of the HiTEC (Hannover Institute of Technology) of the Leibniz Universität Hannover at lzh.de/en/moonrise.