Highly stable steel-aluminium joints for lightweight ships

In shipbuilding the usage of lightweight constructions such as steel-aluminium dissimilar joints are increasing: the hull is made of steel and the superstructure of aluminium. This lowers the ship's centre of gravity while increasing stability and reducing weight. This saves fuel and therefore also CO2-emissions. Until now, the two metals have been joined together using adapters, which are produced through complex and dangerous explosion welding. In the FOLAMI joint project, LZH scientists optimised the laser welding of steel-aluminium dissimilar joints as an efficient and safe method.

Intersecting laser beams ensure high stability

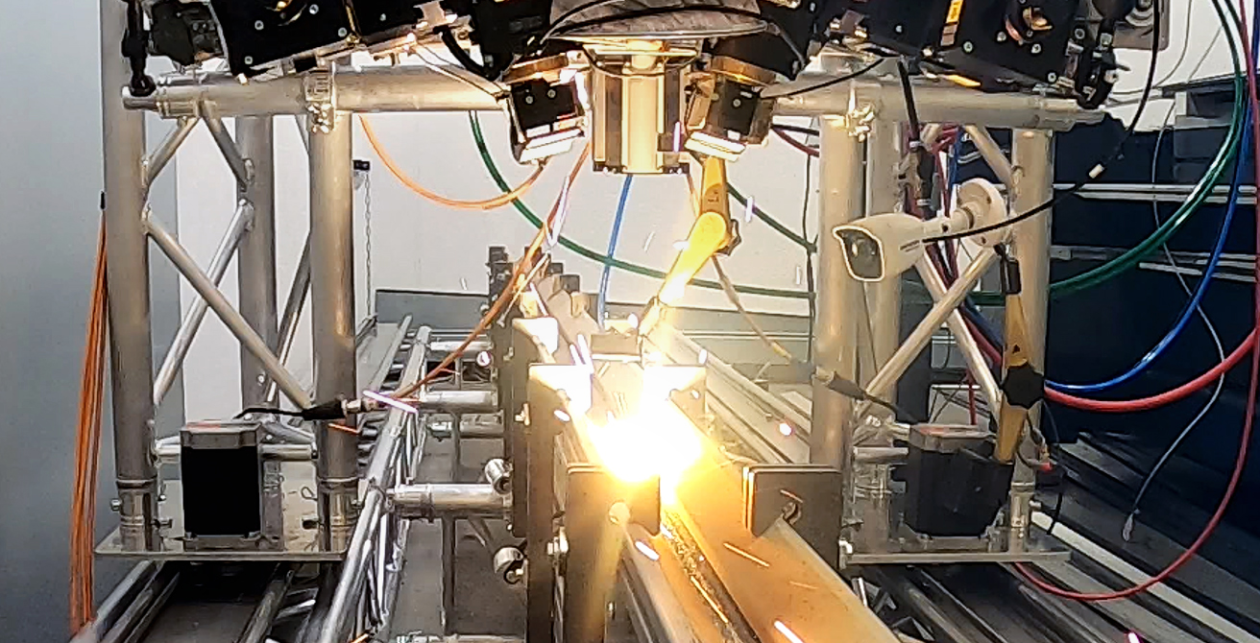

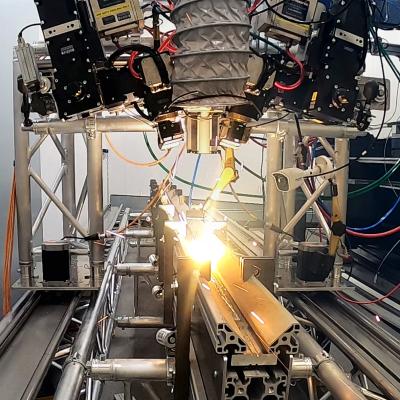

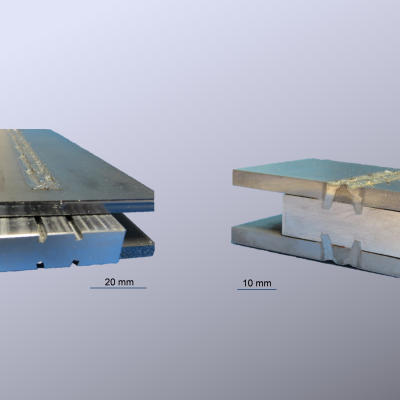

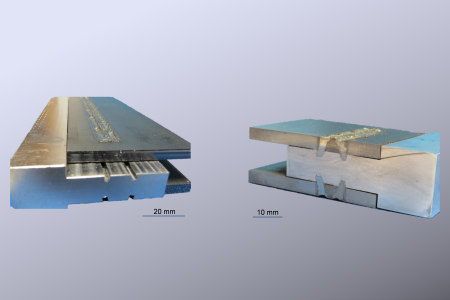

In explosion welding, components are joined through controlled explosion. The force of the explosion collides and welds the two units together without creating a melt. In the sub-project ‘Laser beam welding of form-fit steel-aluminium dissimilar joints using in-process control of penetration depth’, LZH researchers have developed a reliable and efficient method for laser beam welding of this joint. In the process, elongated grooves are first milled into the aluminium alloy sheet and filled with iron powder. The steel is then welded to the aluminium alloy using two intersecting laser beams. A stable process is created due to the reduced aluminium content in the weld metal, while at the same time a form fit is created. This approach leads to a deformable, strong structure with few imperfections and high material strength compared to non-positive, structure-modified dissimilar joints. The researchers also determined the maximum cross tension force of around 12 kN on sheets positioned in the lap joint, a three-fold improvement. At this force, the yield strength of the steel used with a thickness of 5 mm is far exceeded and plastic deformation of the steel sheet occurs.

Lightweight construction principles in shipbuilding

In order to achieve a process that is as stable as possible and to compensate for production-related inconsistencies, the partners developed welding depth control systems. To do this, they used spectral process emission analysis and short coherence interferometry (OCT - optical coherence tomography). For example, the scientists measure the intensity of the process emissions during welding in spectrometer-based control of the penetration depth and correlate them with the penetration depth. Their findings show that the intensity and the welding depth are interdependent. Consequently, this can be used to control the welding depth. If this is maintained, by keeping the penetration depth constant at the desired value, a seam with a high load-bearing capacity can be achieved.

Steel-aluminium adapters enable maximum stability

With the optimised laser beam welding process, the project partners were able to produce adapters with very good strength values. Thanks to the form-fit and the modified microstructure, the laser-welded adapters can withstand a high load of at least 35 kN, which is higher than the force at the yield point of the aluminium alloy used. Last but not least, the adapters impress with their high cyclic load-bearing capacity. The laser-based joining process can be a reliable and efficient alternative to explosion welding and therefore has great potential for use in the shipbuilding sector.

About FOLAMI

The FOLAMI project was coordinated by B.I.G. Technology Services GmbH. In addition to the LZH, the following companies also contributed: Precitec Optronik GmbH, LASER on demand GmbH, the Fraunhofer Institute for Structural Durability and System Reliability (LBF), Hilbig GmbH, Fr. Lürssen Werft GmbH & Co KG, MEYER WERFT GmbH, Coherent Deutschland GmbH and DNV SE. The project was funded by the German Federal Ministry for Economic Affairs and Climate Protection as part of the ‘Maritime Research Programme’ (funding reference 03SX547B), under the technical management of Projektträger Jülich (PtJ).

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. Supported by the Lower Saxony Ministry of Economics, Transport and Building, the LZH is dedicated to selflessly promoting applied research in the field of photonics and laser technology. Founded in 1986, almost 200 employees are now working at the LZH.

The LZH offers solutions to current and future challenges with its smart photonics. Along the process chain, natural scientists and engineers work interdisciplinary together: from component development for specific laser systems or for quantum technologies to process developments for a wide variety of laser applications, for example for medical and agricultural technology or lightweight construction in the automotive sector. 17 successful spin-offs have emerged from the LZH to date. Thus, the LZH creates a strong transfer between fundamental science, application-oriented research, and industry - and uses light for innovation.