New coatings for efficient and compact UV laser systems

A compact, energy-efficient laser system for precise measurements and for the medical market – the Laser Zentrum Hannover e.V. (LZH) was working together with three partners in the Eurostars project CELL-UV to achieve this. The scientists at the LZH have improved the functional coatings of the optics used in order to increase the output power and efficiency of existing laser sources in the UV range (355 nm).

Durable, power-stable optics with low absorption rates are a prerequisite for energy-efficient laser systems. The Coatings Group of the LZH has therefore chosen ion beam sputtering (IBS) for coating the optical components. This coating process enables a high density of optical coating layers, which makes them especially stable and resistant to high laser output. In order to reduce the absorption and diffusion of the optics, two approaches were investigated: a combination of coating materials, and the use of an additional ion beam source.

New material combination: HfO2 and Al2O3

In order to reduce the absorption and diffusion of the hafnium oxide used in the UV range, materials with lower losses in these areas should be added. The scientists used a mixture of hafnium oxide (HfO2) und aluminum oxide (Al2O3) for the optical coatings. Using this approach, the partners could reach a laser system output power of 60 mW in a laboratory setting.

Layer optimization through ion irradiation

Using an additional ion source during the IBS process increased the energy of the particle build-up and decreased the diffusion of the layers. Also, the additional source makes it possible to remove layers that have already been deposited in a controlled manner and without damaging the coating. If this process is used during certain phases of the coating process, it reduces the absorption of the coating layers. The scientists determined the layer thickness curve during the ongoing process using the optical wideband monitor (BBM) developed at the LZH.

About CELL-UV

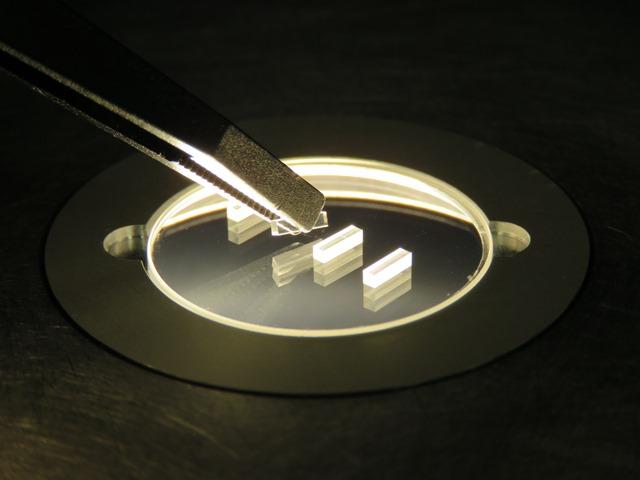

Apart from the LZH, partners in the Eurostars project CELL-UV (Compact and Efficient Laser for Life science and other applications, emitting > 60 mW continuous-wave radiation at 355 nm) were the Cutting Edge Coatings GmbH (Hannover), who supplied the coating technology, and the HC Photonics Corp. (Taiwan), who provided the required frequency conversion crystals. The project was coordinated by the COBOLT AB (Sweden), who will further develop the system for series production.