LASER - World of PHOTONICS 2023: Laser Development

Contact

Phone: +49 511 2788-419

Email: messe@lzh.de

Customized Lasers

Modular and flexible platform for industrial laser development

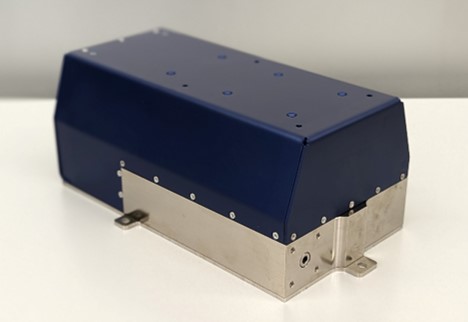

Compact high pulse energy solid-state laser

Modular and flexible platform for industrial laser development

Motivation

• Development of a compact but flexible and modular platform for versatile laser development for industrial applications

• Provide short development times for customized laser sources

Function / Properties / Characteristics

Multiple choices of:

• Seed sources: Q-switched Diode Pumped Solid State Laser (DPSSL) or laser diode seed (~15 ps pulsed to cw)

• Amplification stages: Pre-amplifier plus optional booster stage up to 100 W

• Optional frequency conversion: Second harmonic generation (515 nm) and/or third harmonic generation (343 nm)

• Driver and control electronics integrated in compact package

Applications

• Material processing

• Pulse-on-demand

• Micromachining

• Spectroscopy

• TOF measurement

• OPO or Ti:Sapphire pumping

• Remote sensing

Compact high pulse energy solid-state laser

Motivation

• Development of a compact nanosecond pulsed laser with 100 µJ pulse energy in the green spectral region

Function/ Properties/ Characteristics

• Diode Pumped Solid State Laser (DPSSL)

• Cr4+:YAG for passive Q-Switching

• Compact size: 115 mm x 185 mm x 22 mm (WxLxH)

Applications

• Material processing

• Micromachining

• Spectroscopy

• TOF measurement

• OPO or Ti:Sapphire pumping

• Remote sensing

Parameters

• Pulse energy: 100 µJ

• Pulse repetition rate: 50 kHz

• Pulse length: 2 ns

• Wavelength: 515 nm

• Passive cooling for crystals and pump diode

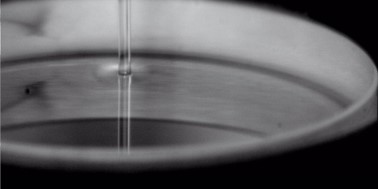

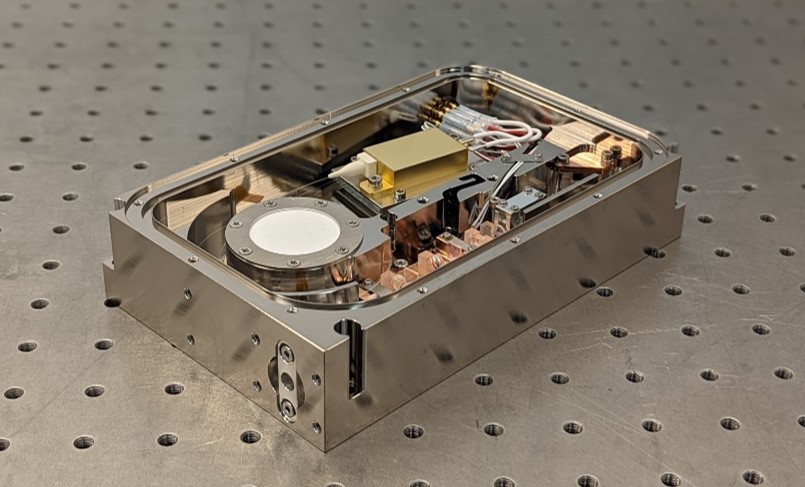

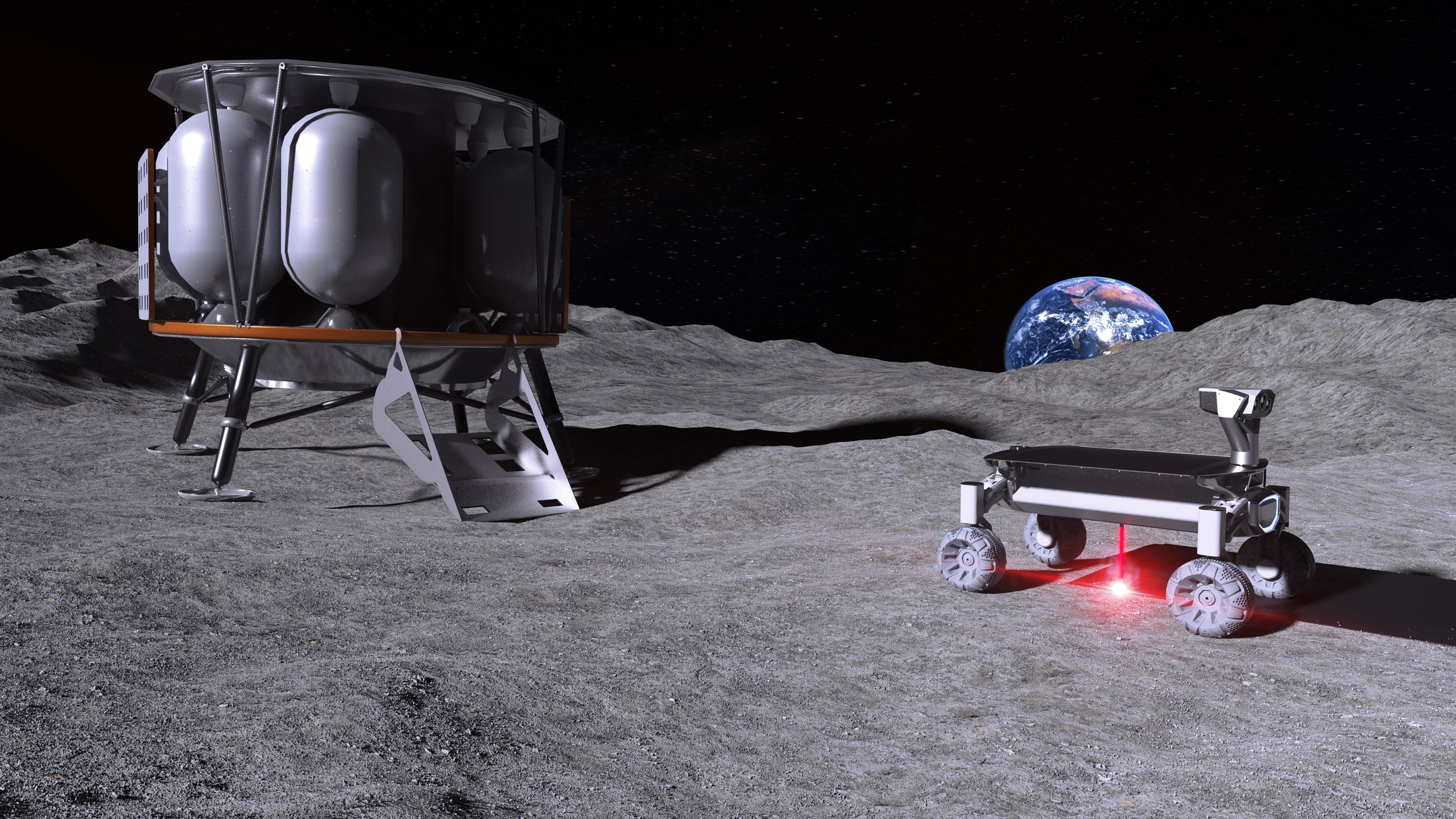

MOONRISE

3D-printing on the moon

In the MOONRISE project, scientists are bringing 3D printing to the Moon. The goal is to explore how we can use lasers in the future to create landing sites, roads, or buildings from lunar dust, also known as regolith. Together with the Institute of Aeronautics and Astronautics at the TU Berlin, the LZH will bring a laser system to the Moon to test the laser melting of regolith.

The use of artificial intelligence (AI) is also to be tested. A camera on the Moon will take pictures of the landing site and the processed lunar dust, which will then be evaluated using AI. In the future, AI could thus help to find a suitable place for laser processing and enable AI-based quality control.

The goal is to show that laser melting works on the Moon – and, in perspective, can be used to produce 3D-printed infrastructure for a lunar base.

Find more information on the project here.

Motivation

• Additive manufacturing of lunar infrastructure with regolith to reduce space transport efforts

• Develop a MOONRISE flight model and demonstrate the laser-based melting of regolith on the Moon

• Testing of the use of aritificial intelligence (AI) for choice of processing location and AI-based quality control of processed material

Function / Properties / Characteristics

• Optical output power: 6-140 W, typ. 70 W

• Mass: ~2 kg

• Dimensions: 10 cm x 10 cm x 15 cm

• Distance to ground: 230 +/- 30 mm

• Operating temperature (tested): -50°C - +70°C

• Mobility: Mounting on a rover/robotic arm

• Experiment verification: Visualization of melted regolith by external camera

Applications

• In situ resource utilization (ISRU) for construction on the Moon

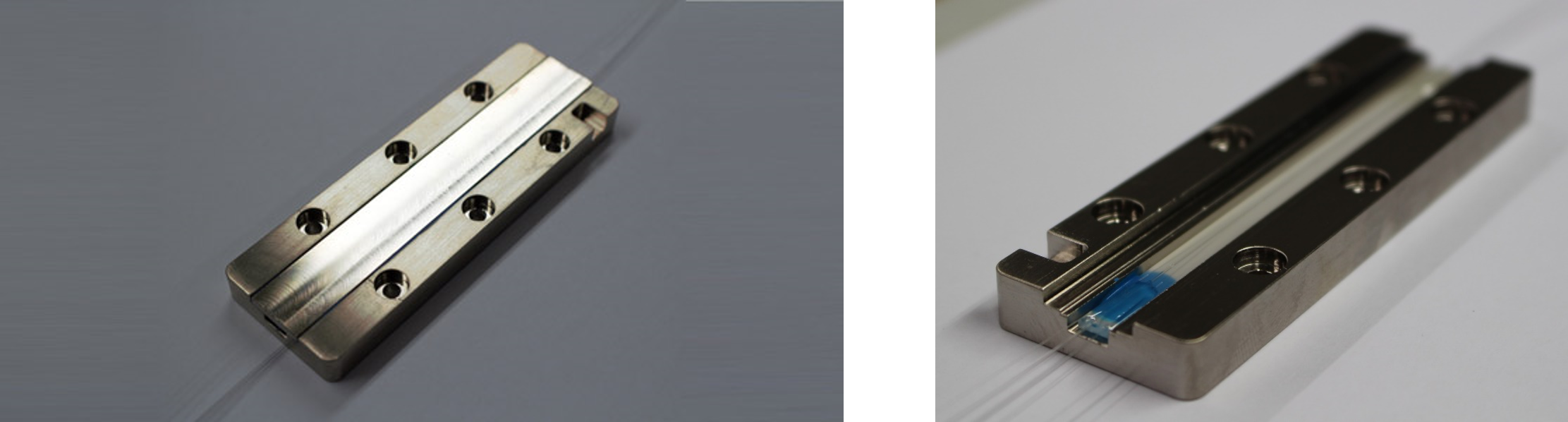

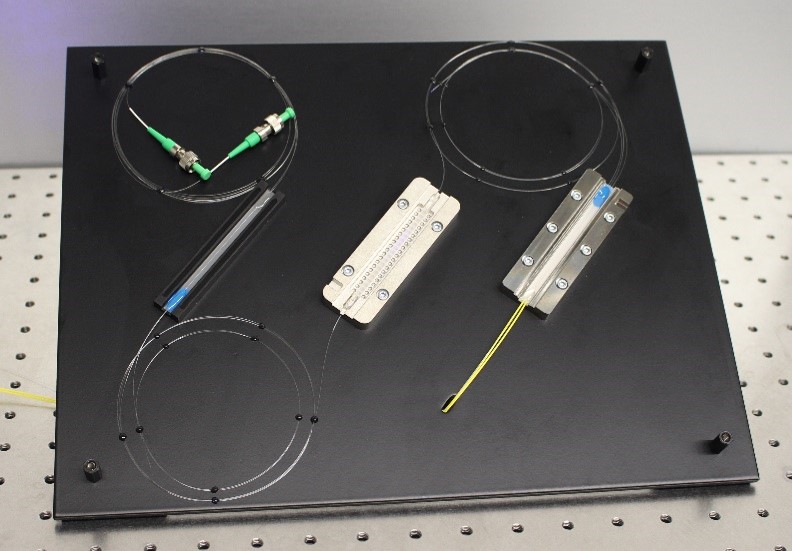

Fiber optical components for fiber amplifiers

Fiber-optical components like signal-pump-combiners, cladding light strippers, beam splitters, end caps and mode field adapters form the basis for the development of fiber laser and amplifier systems. They allow for a high degree of optical and mechanical stability as well as for a high system integration. The Fiber Optics Group at the Laser Zentrum Hannover e.V. focused on developing novel fiber components and improving existing designs regarding the integration of specialty fiber types. If you are interested in our work, please have a look at our latest research:

Signal-pump combiner with chirally-coupled core fiber:

https://www.doi.org/10.1364/OE.455606

Laser engraved cladding light strippers:

https://www.doi.org/10.1364/AO.57.006640

Fully fiber-based single-frequency amplifier system:

https://doi.org/10.1364/OE.27.028523

Motivation

• Integration of specialty fiber types (PCF, CCC-fiber, Triple-Clad fiber, etc.)

• Spliceless fiber laser and amplifier designs

• From simulation to production

Function/Properties/Characteristics

• High power optical components for various wavelengths

• Low signal loss

• Maintains linear polarization and fundamental mode

• High power capable > 1 kW

Applications

• Development of novel fiber laser and amplifier sources

• High average cw power

• Ultra-short pulse generation

• High beam-quality

• Efficiency scaling

Signal-pump-combiner (SPC)

Parameters

• Various signal & pump wavelengths

• High power operation > 600 W pump power

• High PER >20 dB (typ.)

• Low signal loss <0.2 dB (depends on configuration)

• >90% pump power coupling efficiency

• Various signal fibers:

• Up to 400 µm cladding diameter

• Ge-, Er-, Yb-, Tm-doped fiber cores

• Up to 4 pump fibers (typ. 106.5/125 µm or 200/220 µm, NA=0.22)

Application

• Inserting the pump power into the gain-fiber of a fiber-based laser or amplifier system

Cladding light stripper (CLS)

Parameters

• Various signal and pump wavelengths

• High PER >20 dB (typ.)

• Low signal loss

• Stripping power up to 500 W

• High power packaging available

• Optional: with fiber end cap

Application

• Removing redundant cladding light to protect the surrounding system

Wavelength division multiplexer (WDM)

Parameters

• Various signal and pump wavelengths

• High PER >20 dB (typ.)

• Low signal loss

• Power handling >200 W

Application

• Beam splitting

• Filtering and combining signals of different wavelengths

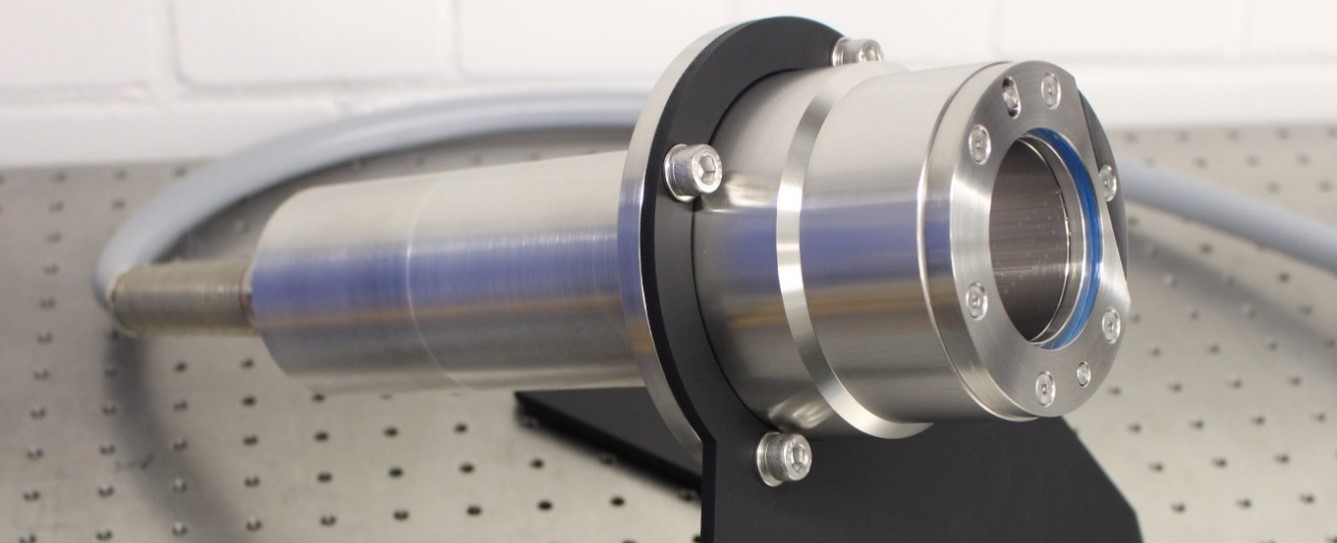

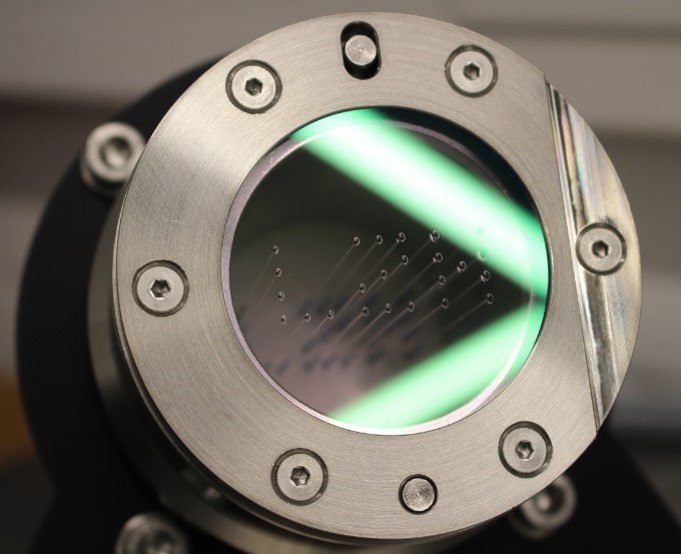

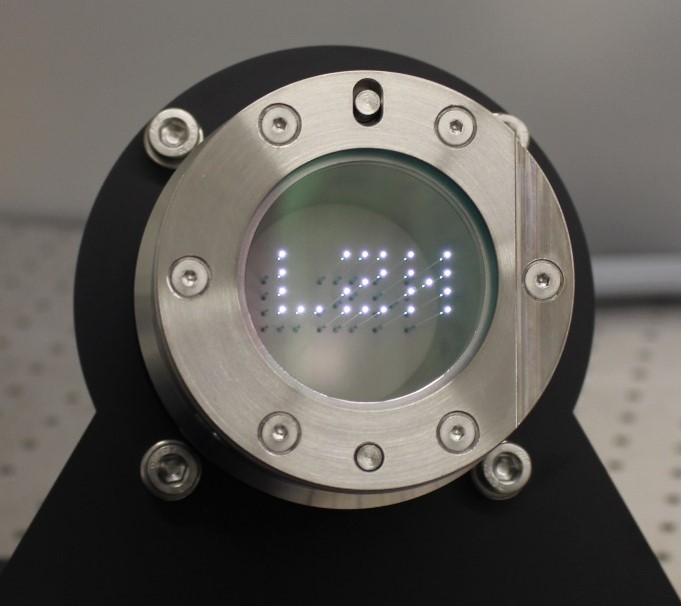

Fiber array in high-power housing

High-power housings for fiber arrays and end caps in general are designed for high heat dissipation. Thermal drifts are thus reduced to a minimum. The welded fibers are aligned with the housing for targeted beam guidance. Additionally, the end facet of the fiber is protected from external influences by the fused substrate

Possibilities:

• Different housing materials and designs for specialized applications

• Cladding light strippers can be integrated into the housing

• Different end caps and fibers can be used

• Current research covers investigation for specialty fibers like for example chirally-coupled-core fiber (CCC) and hollow-core fiber (HCF)

Motivation

• Extension of the possibilities for beam guidance and transmission

Function / Properties

• Fiber array in water-cooled high-power housing

• Stabilizing and protecting the sensitive fiber-to-endcap-connections

• Minimizing thermal drifts

• Dissipates power losses

• Various possibilities for fiber positioning in the housing

Applications

• Protects fiber end facet

• Coupling/decoupling of high laser power

Parameters

• Single or multiple fibers per end cap (variable fiber spacing)

• Fiber to fiber positioning accuracy <10 µm

• Power handling up to 2 kW signal power per channel

• High power packaging available

• Various wavelengths / laser sources

• High PER >20 dB (typ.) and low signal losses

• Various signal fibers:

• Up to 400 µm cladding diameter

• Ge-, Er-, Yb-, Tm-doped fiber cores