New fiber components improve industrial manufacturing

Making production processes more flexible and efficient: In the BMBF project PROLASE, the LZH developed long-term stable and cost-effective fiber components for the reliable dissipation of high optical power losses.

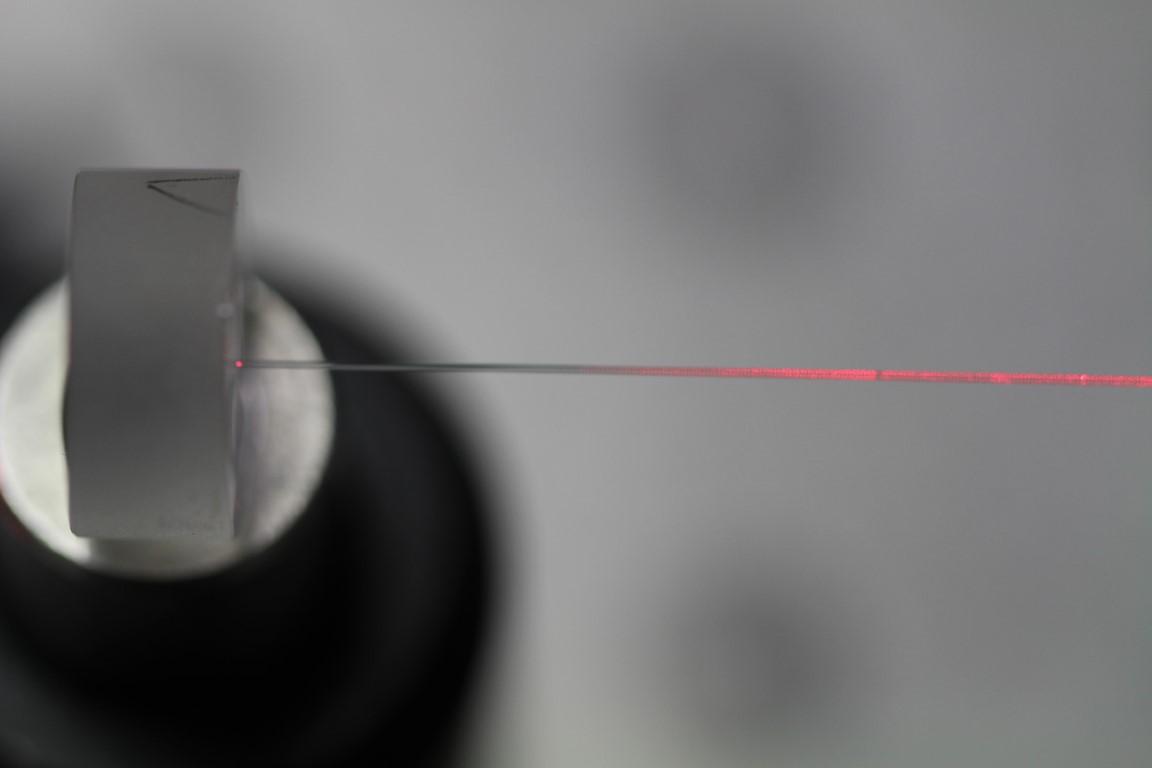

Fiber and diode lasers are often used in industrial manufacturing. A fiber optic beam guidance to the workpiece is often necessary to meet the high stability requirements of the process. In such fiber-based laser systems, cladding light strippers are used to dissipate the optical power loss in a safe and targeted manner. The functioning of such a cladding light stripper is based on a targeted disturbance of the total reflection in the glass fiber over a length of a few centimeters. The scientists at the LZH developed a laser-based process in which the glass fiber surface of the jacket is structured with a CO2 laser. Compared to the previously used etching processes, the process is faster and suitable for laser radiation of all wavelengths, even at high powers.

More information (in German): https://www.photonikforschung.de/service/nachrichten/detailansicht/neue-faserkomponenten-verbessern-industrielle-fertigung.html