A system that rivals conventional processes in terms of speed without any tool wear brings the laser drilling of composite materials a big step closer to application in aircraft construction.

Composite materials such as carbon fiber reinforced plastics (CFRP) are ideal for lightweight construction. As a result, there is great interest in these materials in, for example, the aircraft and automotive construction industries. But the relatively high manufacturing and processing costs for these materials still prevent their widespread use. Automated and easy-to-use laser systems could make composites more attractive to these markets.

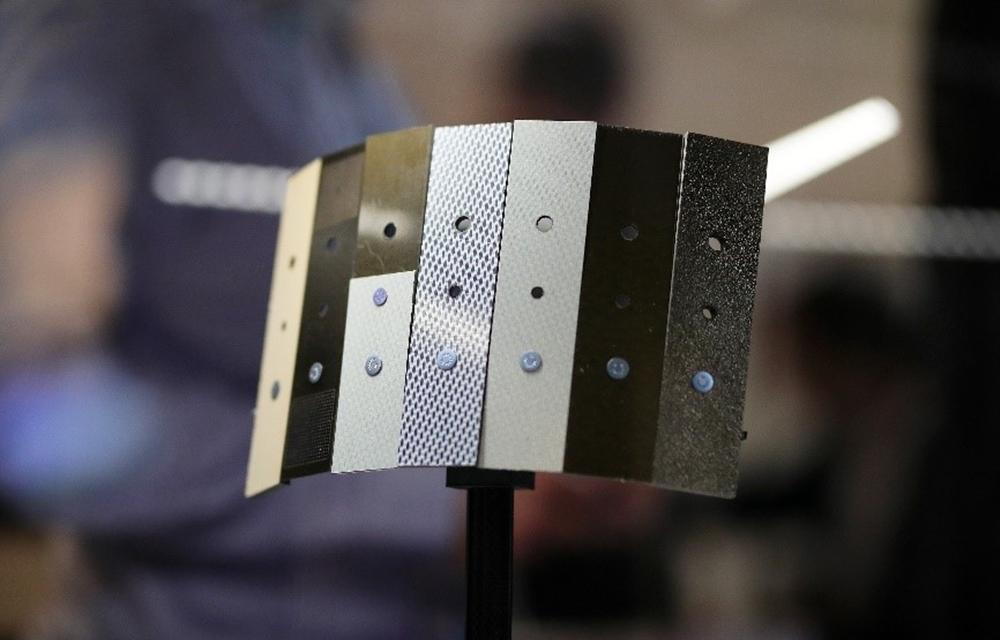

Drilling high-quality holes in CFRP is a challenging process. On average, manufacturers drill 34,000 holes in the A350 fuselage section 13/14 alone during the production of an aircraft. Conventional drilling tools wear out quickly. To meet the exceptionally high quality requirements of the aviation industry, manufacturers have to change the drills frequently. But this is time-consuming and costly. If the tools are changed too late, conventional milling and drilling quickly lead to quality defects, such as delamination, high heat input, undesirable indentations on the sidewalls, and dimensional deviations.

Would you like to find out more? You can find the full article in the online magazine phi - production research Hanover.