Contact

Telefon: +49 511 2788-155

E-Mail: messe@lzh.de

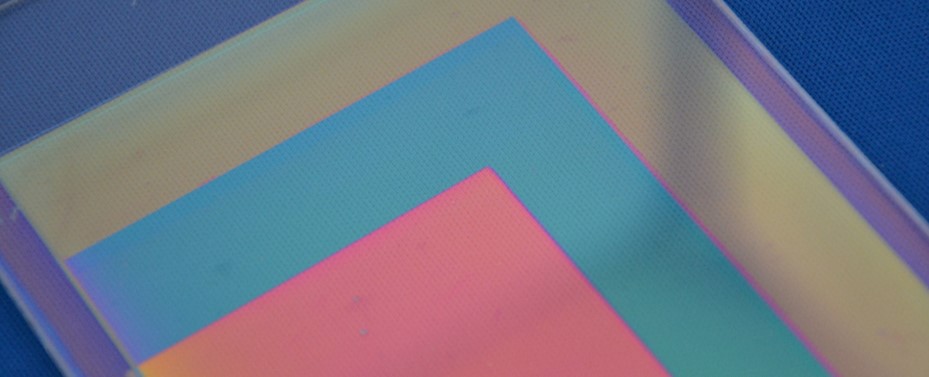

Sol-gel Coating

For the laser annealing of sol-gel layers, the laser beam is guided over the glass sample with the use of a galvanometer scanner or an axis system. In this process, a liner raster is traced to create a homogeneous heat front and shifted over the substrate. The local heating by the laser radiation leads to densification of the sol-gel layer and enables selective densification of areas and shapes of different sizes as well as lettering. After each laser densification performed, the demonstrated sample was recoated and laser-treated again until three fully annealed layers were produced.

Motivation

• Sol-gel coatings are commercially annealed by using a furnace

• For a profitable process, the furnace needs a high capacity utilization rate

• More energy-efficient annealing by the use of laser radiation

• Processing of various sol-gel materials is possible

Function / Properties / Characteristics

• Achieve equal or higher refractive indices with the laser compared to furnace annealing

• Homogeneous layer formation

Applications

• Color effect glasses

• Optical filters

• Improvement of the corrosion and wear resistance (depending on the material: zirconium

dioxide)

Parameters

• Scanning speed: 2000 mm/s for layer one and two

3000 mm/s for layer three

• Focus diameter: approx. 830 µm

• Laser power: 60 W

Laser sources

• CO2-Laser: 10.6 µm

Processed material

• Borosilicat glass

• Three layers of titanium dioxide

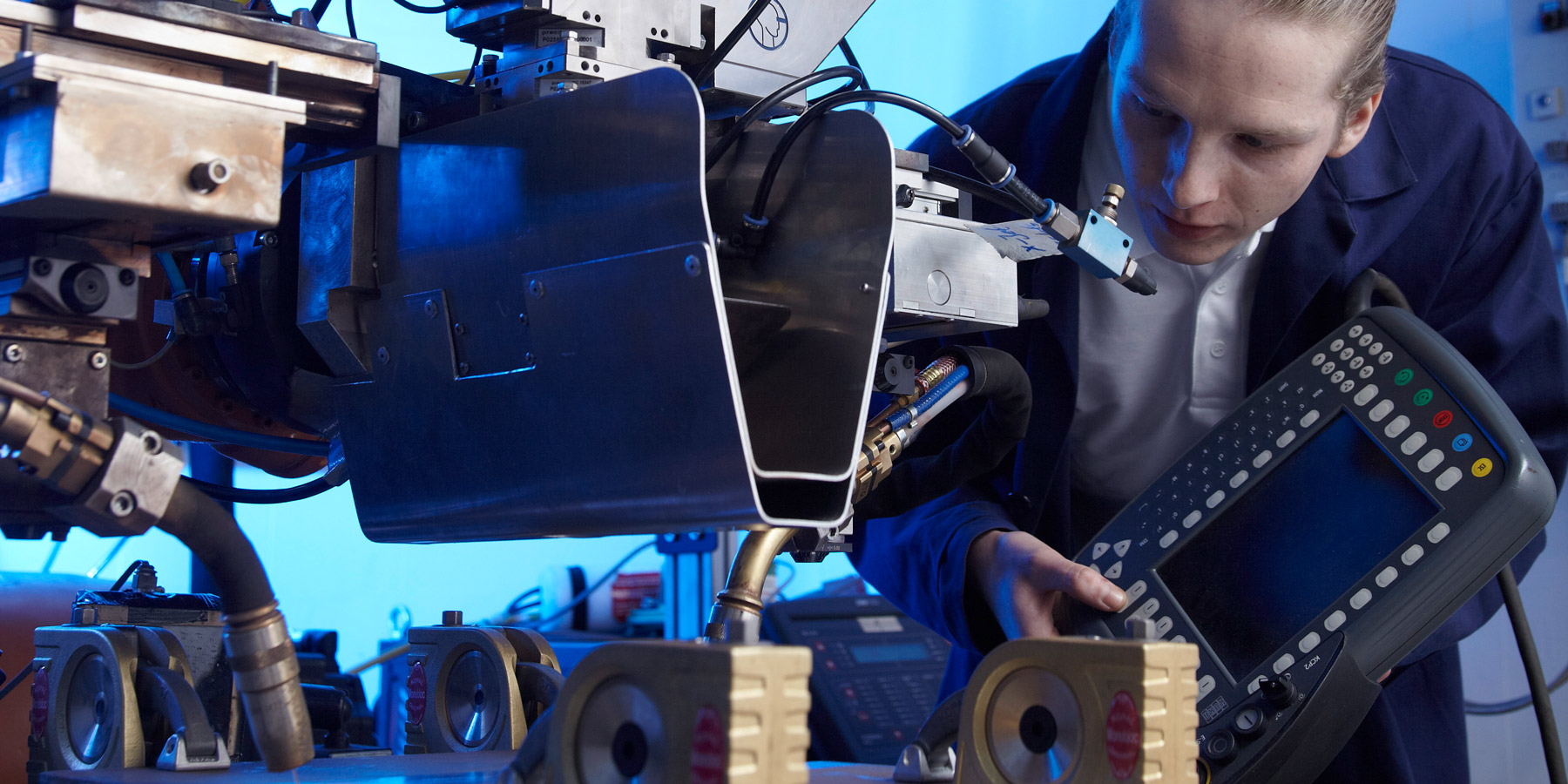

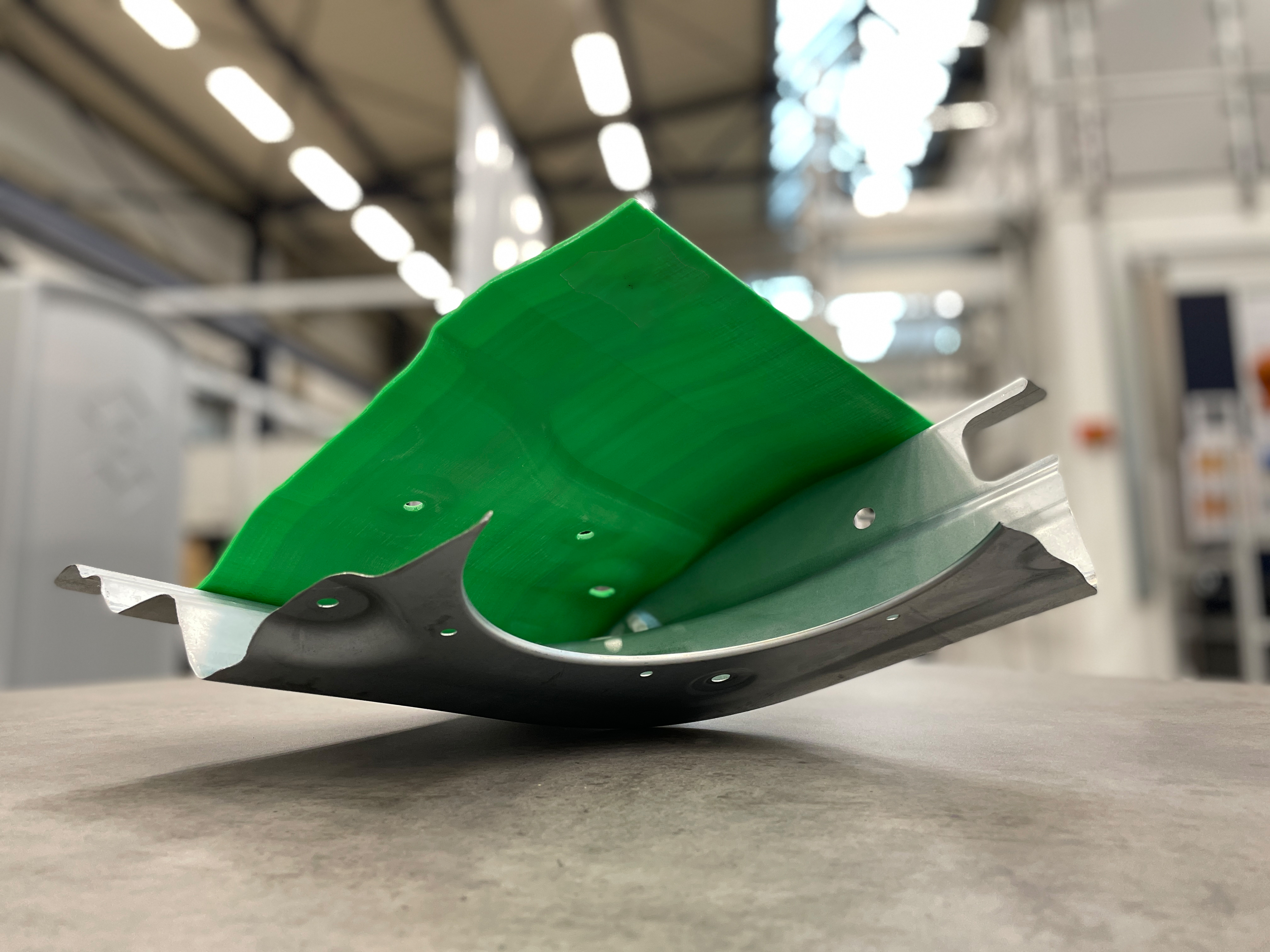

Multispot

Motivation

• Meet the demands of each weld seam geometry

• Adapt the desired intensity distribution within a laser focus

Function / Properties / Characteristics

• Nine individual modularly controllable laser spots

• Partially adapt the laser power to both the weld seam geometry and the material properties

Applications

• Laser transmission welding of unreinforced and reinforced thermoplastics

• Heat conduction welding of carbon fiber reinforced thermoplastics

• Laser joining of thermoplastics to metals

Laser source

• Diodelaser

• Wavelength 980nm

• Max. Power up to 1kW

• 9 individual controllable laser spots

Processed material

• Thermoplasics such as PA6, PE, PP, PPS, PEI

• Carbon fiber reinfroced thermoplastics

• Joining of metal-thermoplastic hybrid parts

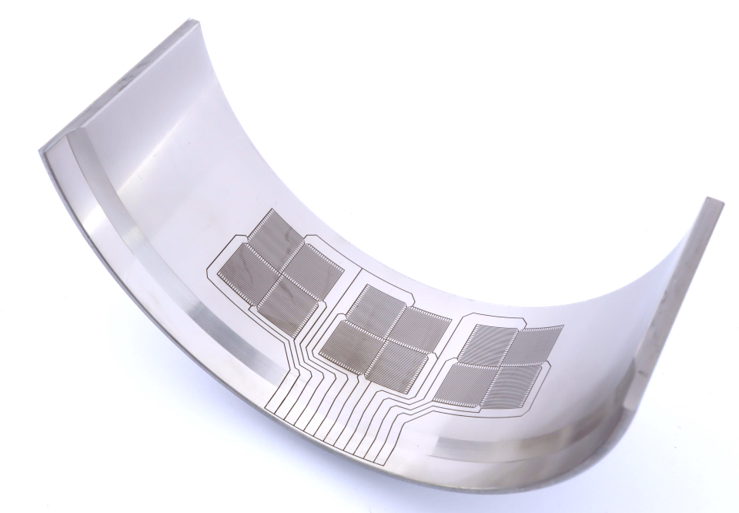

Thin-film sensors

Motivation

• Improvement in the performance and robustness of large engines by condition monitoring

• Integrated sensors and digital systems enable condition-based maintenance, reduction of downtime, and prevention of wear or damage by appropriate control strategies

Characteristics

• Bearing shell with laser patterned thin film strain sensors

• A wear protection layer embeds the sensor system to prevent damage from abrasion

• The sensors measure deformation and temperature in close proximity to the oil film between

journal and bearing during operation of the engine

Thin Film Deposition

• Dielectric isolation layer

• Sensor layer

Laser Patterning and Trimming

• Selective film removal by laser ablation / 3D surfaces

Connecting and Embedding

• Soldering / Wire bonding

• Additional protection layer or encapsulation

Thin Film & Laser Technology

• Flexible patterning process for 3D surfaces

• Highly integrated: Thickness less than 10 µm

• Thin film system deposited directly on surface: Robust, low drift, high temperatures

• High-precision resistor trimming process, tolerance < 0.1 %

Applications

• Force and stress measurement on components (3-D surface)

• Example applications: precision measurement on force-translating components, sensor

technology, thin-film electronics on component surfaces

Drilling of CFRP

Motivation

• >150 000 000 drilling operations performed per year in the german aviation industry

• High tool wear when machining CFRP with drill bits

• High quality and high accuracy required

Function / Properties / Characteristics

• No tool wear with laser drilling

• Flexibility in bore diameter and drilling pattern without tool change

• Multi-material stacks drillable

• High quality and high accuracy:

• Heat affected zone <40 µm, drilling without taper achievable

Applications

• Macro drilling:

• High quality rivet hole drilling

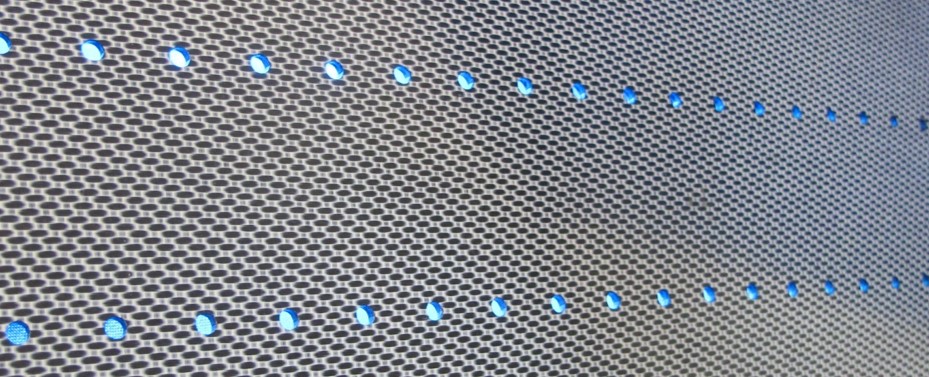

• Micro drilling of large surfaces:

• Noise reduction & sound design in aerospace / automobile / construction industry

• Flow control / boundary layer suction

Parameters

• Remote processing

• Stepwise material ablation

Laser sources

• Nanosecond-pulsed high-power laser by TRUMPF

Processed material

• Carbon fiber reinforced plastics, Glass fiber reinforced plastics, CFRP-Sandwich materials

• Multi-material stacks drillable (e.g. thermoset CFRP laminate with thermoplastic laminate

including GFRP protection layer and copper mesh)

Receive the link to this site per mail

Would you like to access this information again later? Please submit your email-adress here. You will receive a one time mail with the link to the information. . If you would like to stay up-to-date to news from the LZH, you find the opportunity to subscribe to our newsletter or our social media channels in the mail.