LASER - World of PHOTONICS 2022: Optical Components

Contact

Phone: +49 511 2788-238

Email: messe@lzh.de

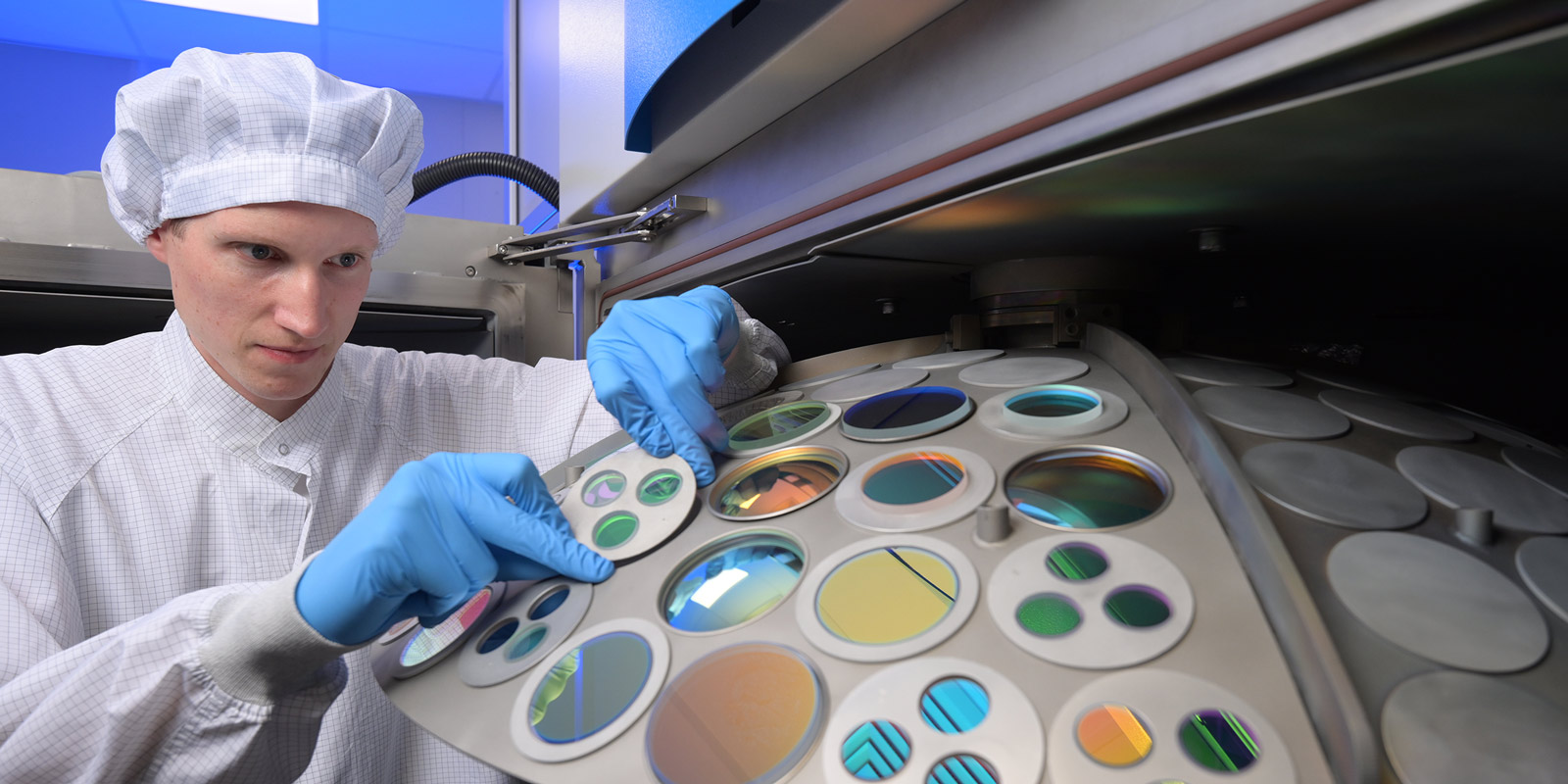

High Resolution Optical Broadband Monitoring

Motivation

• Precise in situ coating thickness monitoring for production of optical thin-film filters

Function

• Direct broadband measurement of moving substrates on rotating substrate holder in UV to NIR wavelength range

Applications

• Precise deposition control

• Online characterization of coatings

• Automated process control

• Rapid manufacturing of complex optical designs

• Faster development of new coating processes

• Quality control and documentation of production processes

• Increased process yield using advanced simulation, re-optimization and error handling tools

• Modular system, flexible configuration according to customer specification in wavelength range and resolution

Technical data

| BBM | HR BBM | |

| Wavelength range | 240 - 1000 nm optional IR: 240 - 1700 nm |

|

| Spectral resolution | 1 - 1.5 nm IR: 1 - 5 nm |

0.1 - 0.2 nm IR: 0.1 - 3 nm |

| Measurement time | 10 µs - 30 ms | |

| Wavelength accuracy | < 0.5 nm | |

| Reproductibility of 100%-measurement | better ±0.04% | |

| Noise of 100%-measurement | < 1% RMS | |

Performance and Options

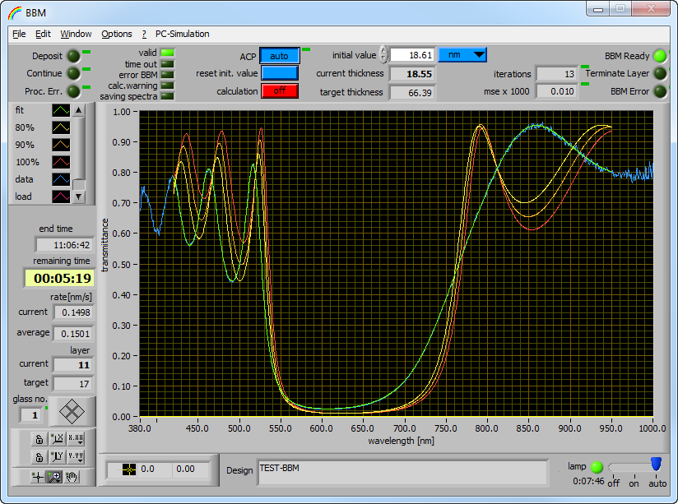

• Software algorithms for data acquisition, thickness determination and process control

• BBM simulation module, including a virtual deposition unit: advanced design stability analysis

• Re-optimization module: online error analysis and automated design refinement for increased yield

• Modular system: options for uniformity measurements on multiple radii, combined transmittance and reflectance measurements, spectral resolution below 1 nm (High Resolution / HR BBM)

• In addition to the standard configuration, customized adaptions, e.g. for spectral range and resolution, are available

Applicability

• System compatibility to nearly all deposition chambers and customer specified instrumentation

• Best applicability to IAD and sputter deposition processes

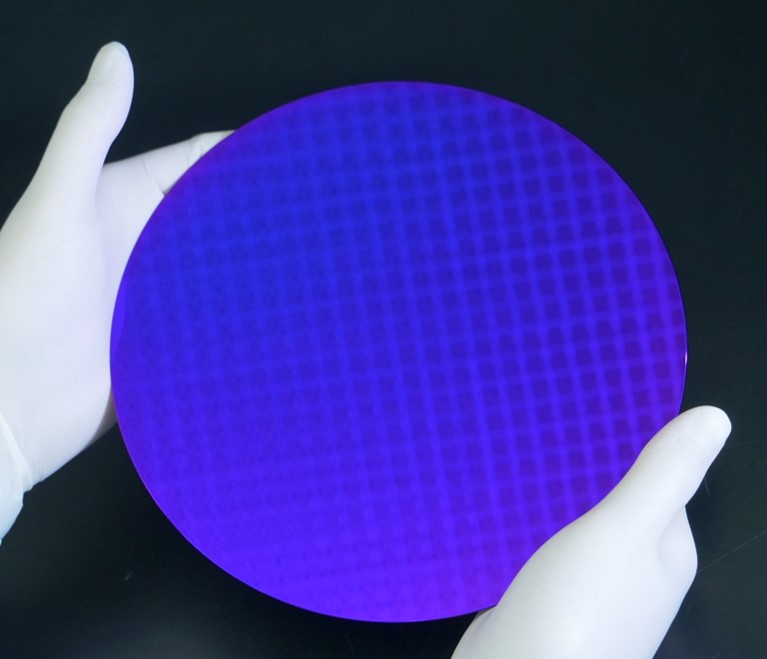

rALD Coatings

Motivation

• Rising form complexity of optics

• CNC milling, polishing

• 3D printed, injection molding, casting

• Need of conformal coatings

• Sensitive materials

Function/Properties/ Characteristics

• High conformal, low temperature coatings

• Large areas up to 200 mm diameter

• Low spectral absorption

Applications

• Planar and non-planar optics

• Aspheres, Fresnel lenses, prisms

• Gratings

• Capsuling

• e.g. laser crystals

Parameters

• ~0.14 nm/sec growth rate

• 150°C deposition temperature

Processed material

• 200 nm Ta2O5

• 8’’ silicon wafer

Sample loading

• Direct or via load lock

Outstanding growth rate

• Up to 1000 nm/h

• Temperature range 25-200°C

Batch size

• 7 pieces 200 mm

• 13 pieces 100 mm

• 384 pieces 25 mm

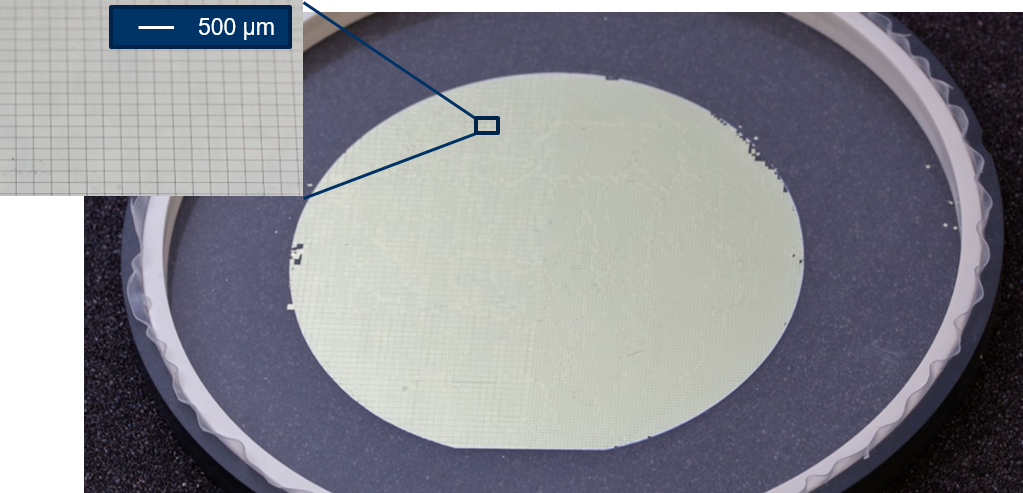

CWDM Filters

Motivation

• Thickness reduction leads to

• less divergence during propagation through filter element

• reduction of beam displacement

• Increase in coupling efficiency

• Only functional layers have to be considered

Function / Properties / Characteristics

• Precise IBS sputtering

• Insertion loss > -0.2 dB at CWL

• Thickness ~ 25 µm

Applications

• Telecom / Datacom

• Coarse Wavelength Division Multiplexing

• Photonic Integrated Circuits

Parameters

• High reflecting zone: 1265 nm – 1617 nm

• Attenuation < -30 dB

• Anti reflection zone: 1305 nm – 1317 nm

• Insertion loss > -0.2 dB

• Size depends on application

• 250 µm x 250 µm for fiber integration

Processing steps

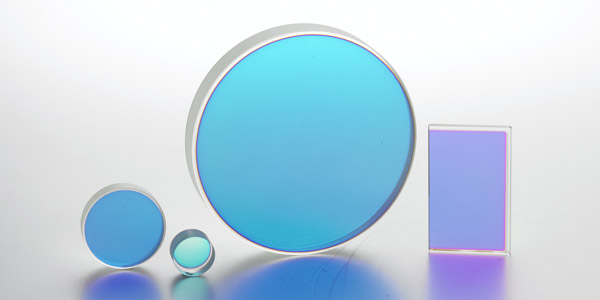

Optical Coatings

Coating technologies

• Ion beam sputtering

• Ion assisted deposition

• Evaporation

Coating types

• AR coatings (single wavelength to broad band, …)

• HR coatings (high finesse, high power, low loss, …)

• Complex Filters (band pass, polarization coupler, …)

• Special substrates (Laser crystals, optical fibers)

• Custom coatings

Applications

• Laser systems

• Space applications

• Astronomy

• Medical applications

• Metrology

Metrology

• Laser-induced damage (ISO 2154-2)

• Laser-induced damage in vacuum (ISO 2154-2)

• Survival tests (ISO 2154-3)

• Absorption Measurements (ISO 11551)

• Cavity-Ring-Down

• Total Scattering

• VUV / DUV spectroscopy

• Durability testing (ISO 9211)

• Spectral photometry 120 nm – 25 µm

Receive the link to this site per mail

Would you like to access this information again later? Please submit your email-adress here. You will receive a one time mail with the link to the information on our exhibits at the LASER - World of PHOTONICS. If you would like to stay up-to-date to news from the LZH, you find the opportunity to subscribe to our newsletter or our social media channels in the mail.