Denser and Smoother Lunar Dust Samples Through Remelting: Advances for MOONRISE

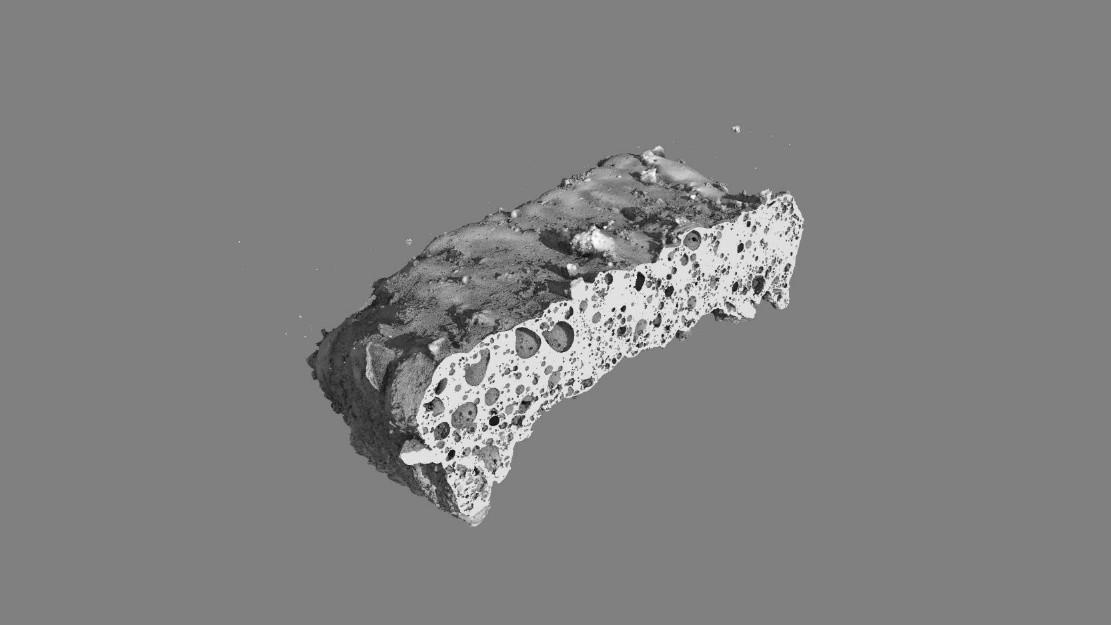

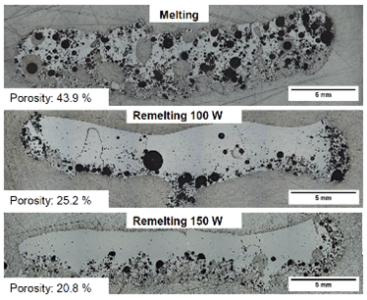

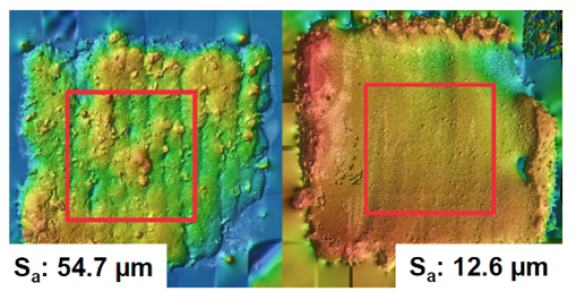

Current research in the MOONRISE project focuses on processing regolith, the sand-like material covering the Moon's surface. As LZH scientists have demonstrated, a second laser pass substantially enhances the properties of the melted sample: Following this treatment, the samples exhibit significantly reduced porosity while the previously rough surface becomes smoother, glossy, and semitransparent. Porosity decreased by 23.1 percent, while surface roughness was reduced by a factor of four.

During laser remelting, adhering unmelted particles as well as large portions of the already solidified material undergo reprocessing. LZH scientist Tim Eismann also reported these findings at the "Workshop of the Toulouse Task Force on ISRU." The resulting samples exhibit glass-like properties in both transparency and hardness.

As next steps, the team will investigate the load-bearing capacity of the samples to determine whether the denser, albeit thinner, samples are better suited as structural elements for lunar infrastructure.