Innovative Additive Manufacturing: LZH at formnext 2025 in Frankfurt

With innovative solutions and practical applications, Additive Manufacturing can provide solutions to challenges across diverse industries. LZH scientists are working on processing challenging materials, for example. These include magnesium alloys, which enable numerous applications in lightweight construction and medical technology due to their low density and biocompatibility. They are also engaged in Additive Manufacturing of glass, which allows for the implementation of new geometries for optical freeform components and waveguide systems in the field of optics, as well as structural components.

Custom Special Equipment and System Technology

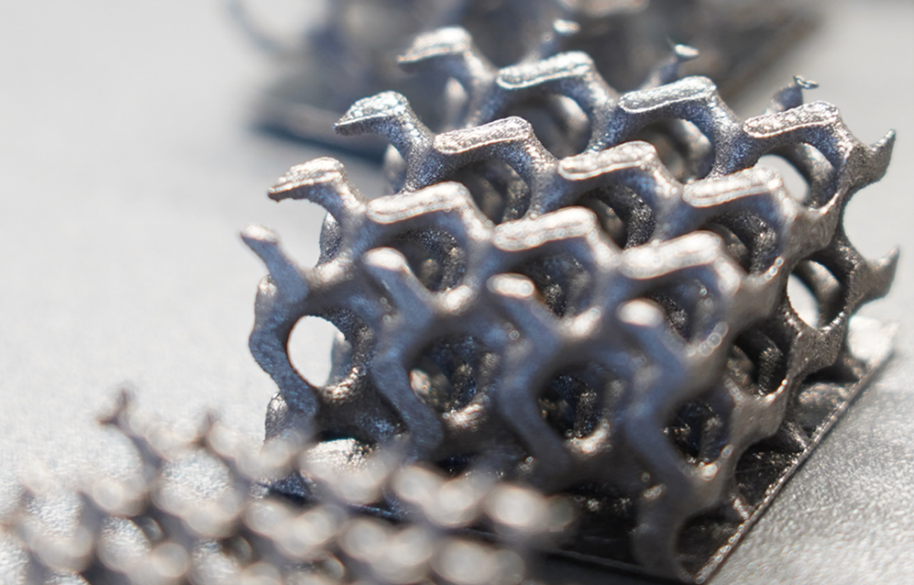

LZH also develops and builds custom specialized systems, for example for manufacturing in oxygen-free atmospheres. Furthermore, the scientists conduct research on the application of new beam sources, manufacture tailored process heads for laser metal deposition, and work on pressure-optimized components. The latter are particularly important for applications such as dental implants.

Sustainability Through Additive Repair Processes

In the area of sustainability, additive manufacturing can contribute to extending the service life of high-value and heavily stressed components. LZH conducts research on laser metal deposition processes and single-crystal deposition welding. This is of interest for mechanical engineering, agricultural technology, and aerospace applications. The scientists demonstrate through initial work how this process can be used to repair large components, such as those from shipbuilding, directly at the deployment site.

Practical Solutions for SMEs, Crafts, and Agriculture

Beyond industrial applications, LZH also addresses the needs of small and medium-sized enterprises (SMEs), crafts, and agriculture. At formnext 2025, LZH will present approaches showing how Additive Manufacturing can help solve everyday challenges. One example is the development of custom tools that make the seed distribution process in agriculture more efficient. This research project emerged from preliminary work in the Niedersachsen ADDITIV project.

Partnership and On-Site Expertise

LZH offers companies comprehensive support in developing new manufacturing technologies. Interested parties can learn about the diverse applications of Additive Manufacturing at the Bremen/Hesse joint pavilion (Hall 12.0, Booth C22). In addition to processing metals, polymers, and glass, funding opportunities and collaborative projects will also be highlighted.

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. Supported by the Lower Saxony Ministry of Economics, Transport and Building, the LZH is dedicated to selflessly promoting applied research in the field of photonics and laser technology. Founded in 1986, almost 200 employees are now working at the LZH.

The LZH offers solutions to current and future challenges with its smart photonics. Along the process chain, natural scientists and engineers work interdisciplinary together: from component development for specific laser systems or for quantum technologies to process developments for a wide variety of laser applications, for example for medical and agricultural technology or lightweight construction in the automotive sector. 17 successful spin-offs have emerged from the LZH to date. Thus, the LZH creates a strong transfer between fundamental science, application-oriented research, and industry - and uses light for innovation.