LZH expands test methods to modern high-performance optics with partners from practice

A limiting factor in developing new laser systems is the optical resilience of the components with which the laser radiation is generated and guided. These are necessary to achieve ever higher optical outputs. At the same time, there is a growing demand for low-weight optical components, for example, for use in galvanometer scanners in material processing.

Ensure performance compatibility of innovative optics

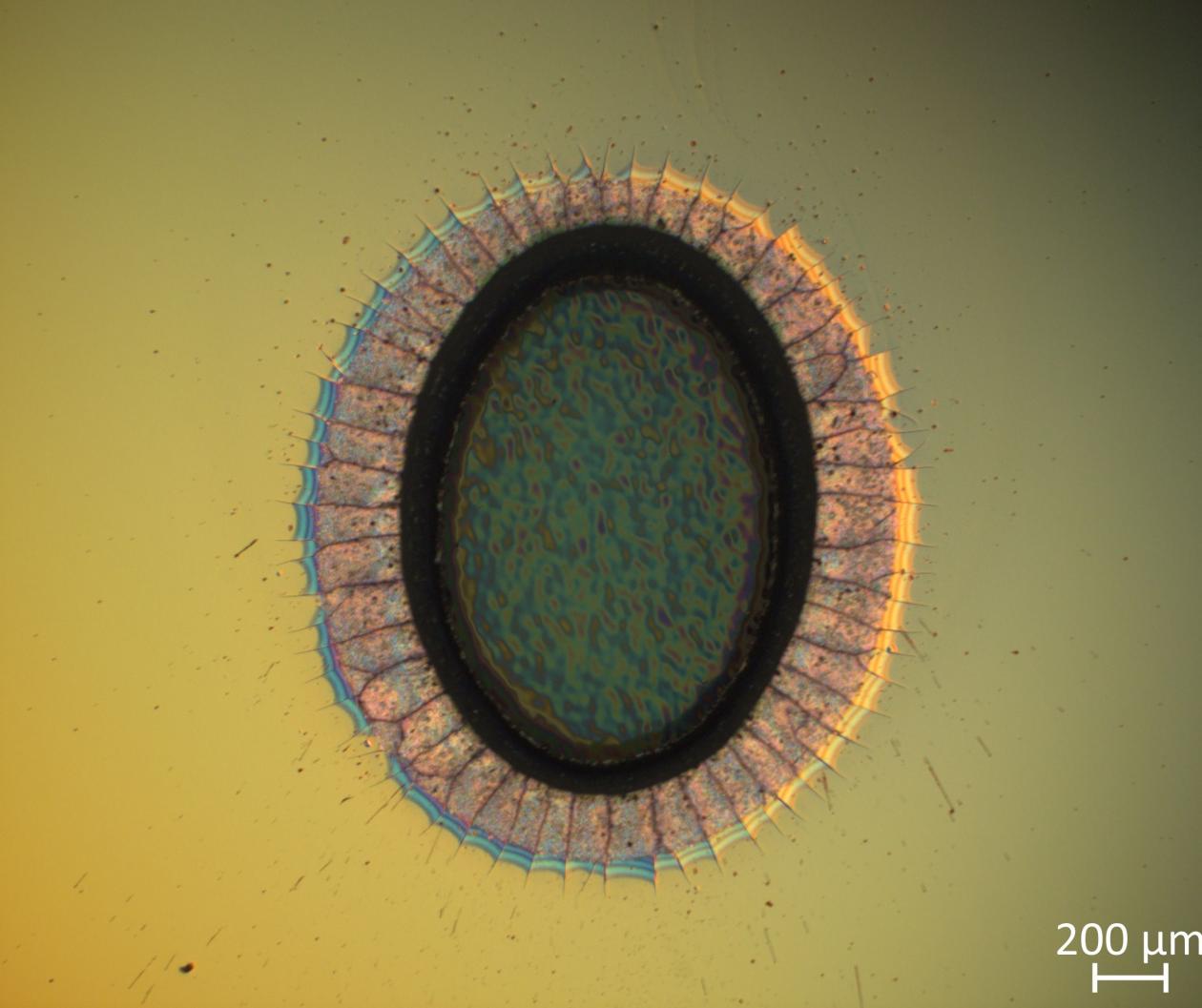

The scientists at the LZH are therefore developing measurement routines in the project to test and consequently guarantee the performance compatibility of such optics. In this context, the previous findings of the established optics tests cannot be transferred without further ado to modern optics with reduced geometry and therefore lower weight. For example, according to ISO standard 21254, the optics is irradiated at 100 positions. This is not possible with smaller surface areas, since the measuring points influence each other, for example through thermal conduction or thermal stresses.

With the new measurement routine, the Photonic Materials group of the LZH investigates different optics and uses the results to create models to make optics even more robust in the future. In doing so, they take into account different materials, geometries, and different manufacturing processes. LASEROPTIK develops optics coatings of the highest destructive strength adapted to special geometries. These components are then inserted into a deflection unit manufactured by RAYLASE and tested by the LZH close to the application, i.e. in the finished module and with parameters similar to the later application. The aim is to develop more stable scanner modules.

About cw-LIDT

In the project "Standardized test method for high-performance optics in continuous wave operation (cw-LIDT)”, the LZH is working together with LASEROPTIK GmbH, Garbsen, and RAYLASE GmbH, Wessling. The project is funded by the German Federal Ministry for Economic Affairs and Climate Action.

The scientists have already published initial results on this: https://doi.org/10.1117/12.2621132

Partner

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. Supported by the Lower Saxony Ministry of Economics, Transport, Construction and Digitalization, the LZH is dedicated to selflessly promoting applied research in the field of photonics and laser technology. Founded in 1986, almost 200 employees are now working at the LZH.

The LZH offers solutions to current and future challenges with its smart photonics. Along the process chain, natural scientists and engineers work interdisciplinary together: from component development for specific laser systems or for quantum technologies to process developments for a wide variety of laser applications, for example for medical and agricultural technology or lightweight construction in the automotive sector. 18 successful spin-offs have emerged from the LZH to date. Thus, the LZH creates a strong transfer between fundamental science, application-oriented research, and industry - and uses light for innovation.