Ausstellung in Berlin mit Laserzeichnungen aus dem LZH

Die Künstlerin Susanne Specht hat am LZH dreidimensionale Kunstwerke aus Papier geschaffen. Die Ausstellung findet vom 10.10. bis 31.12.2021 in der Zitadelle in Berlin statt.

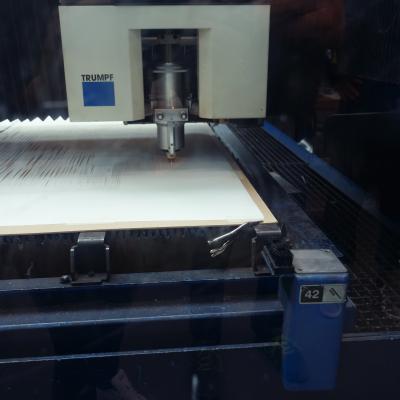

„Von der Fläche in den Raum“ – dieses Thema setzte die Künstlerin Susanne Specht zusammen mit Matthias Schrader, Techniker am Laser Zentrum Hannover e.V. (LZH), auf großflächigem Papier um. Vorausgegangen waren Arbeiten der Künstlerin mit einem kleinen Laserschneidgerät, am LZH war es ihr möglich, Papier mit 2 bis 3 m Länge zu schneiden.

An zwei Tagen im LZH entstanden mehrere langformatige Papiere, die im Raum aufgehängt wie Skulpturen wirken und so vom Standort des Betrachters aus stetig neue Perspektiven eröffnen. Der Laser prägte dabei das Papier mit feinen Schmauchspuren und ermöglichte die Papierbearbeitung im Dreidimensionalen.

Die im LZH entstandenen Arbeiten von Susanne Specht sind in ihrer Ausstellung „ab ovo oder eine Geschichte von Anfang an“ vom 10.10.2021 bis zum 31.12.2021 im Zentrum für Aktuelle Kunst (ZAK) in der Zitadelle in Berlin zu sehen.