Hannover Messe 2024 - Exhibits

Contact

Telefon: +49 511 2788-419

E-Mail: messe@lzh.de

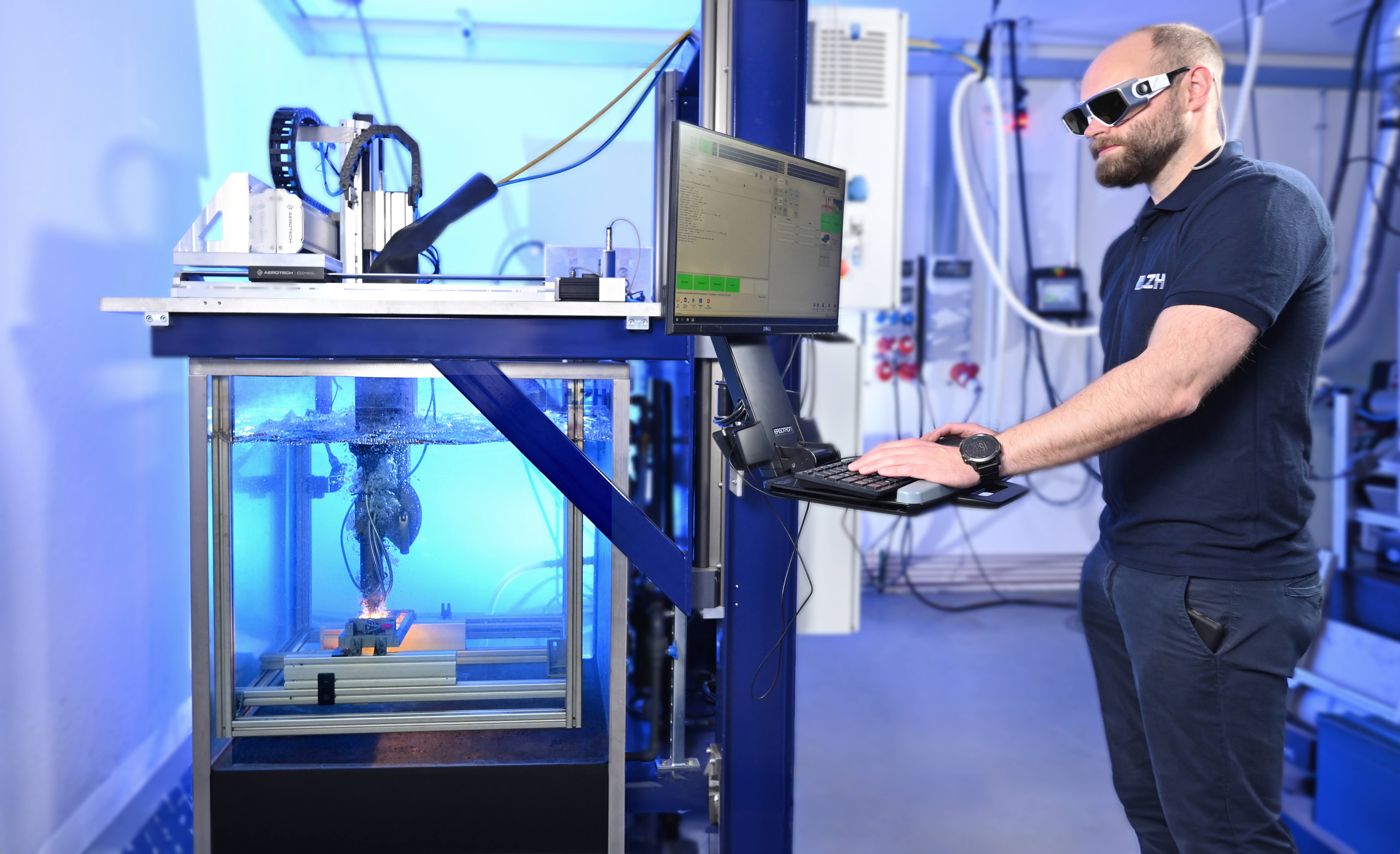

Underwater laser treatment of fouling on ship hulls

LZH scientists, together with partners, are developing an automated, environmentally friendly method to clean ship hulls underwater using lasers. Marine fouling on ship hulls, such as mussels and algae, known as biofouling, increases the hydrodynamic drag of ships, resulting in higher fuel consumption and emissions. The goal is to realize an alternative to anti-fouling coatings.

In this project, LZH collaborates with Laserline GmbH, the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, and OFTEC Handelsgesellschaft für Oberflächentechnik mbH. The team will test and optimize the method and its effects on fouling samples including algae, barnacles, and other marine organisms on test surfaces in Helgoland. The process will be demonstrated on a real ship upon the project’s completion.

At a glance

• Lethal damage to biofouling

• Time-shifted cleaning effect

• Diode laser from Laserline

• Tested hull coatings: SPC, FRV, hard coating

The research project "FoulLas² - Fouling removal from ship hulls using underwater laser radiation based on blue diode direct emitters and an automated/partially autonomous handling system " is funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK) under the funding code 03SX597 by the project management organisation Forschungszentrum Jülich GmbH.

More information:

LZH is researching automated underwater cleaning of ship hulls with laser

Laser against biofouling: Eco-friendly underwater cleaning of ship hulls

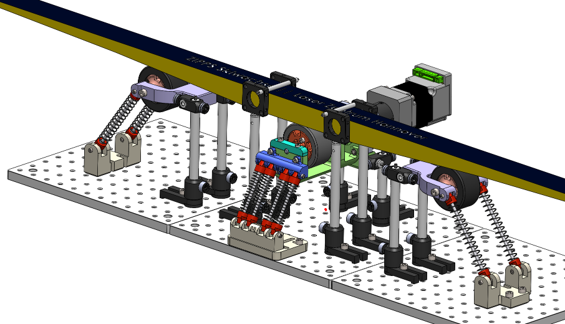

Laser microstructuring of skis

As part of the research project SkiWachs (en: SkiWax), researchers at LZH have developed a method to create special structurings of the ski surface. They used a laser to introduce microstructures into the ski surfaces. Their goal was to develop a friction-reducing surface to provide an alternative to environmentally harmful fluorine-containing ski waxes, which have been banned in skiing since 2023.

At a glance

• Objective: Reduction of friction

• Up to 8 million cavities per ski

• Pulse duration: < 250 fs

• Processing time: 0.5 – 4 h per ski

• Material of ski: Ultra High Molecular Weight Polyethylene (UHMWPE)

The SkiWachs project was funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK) as part of the Central Innovation Program for SMEs (ZIM) under the funding code KK5111702BR0. Project partner was the Zipps Skiwachse GmbH, project sonsor the AIF Projekt GmbH.

More information:

Fluorinated Ski Wax Ban: Skis with Functional Surfaces as an Alternative

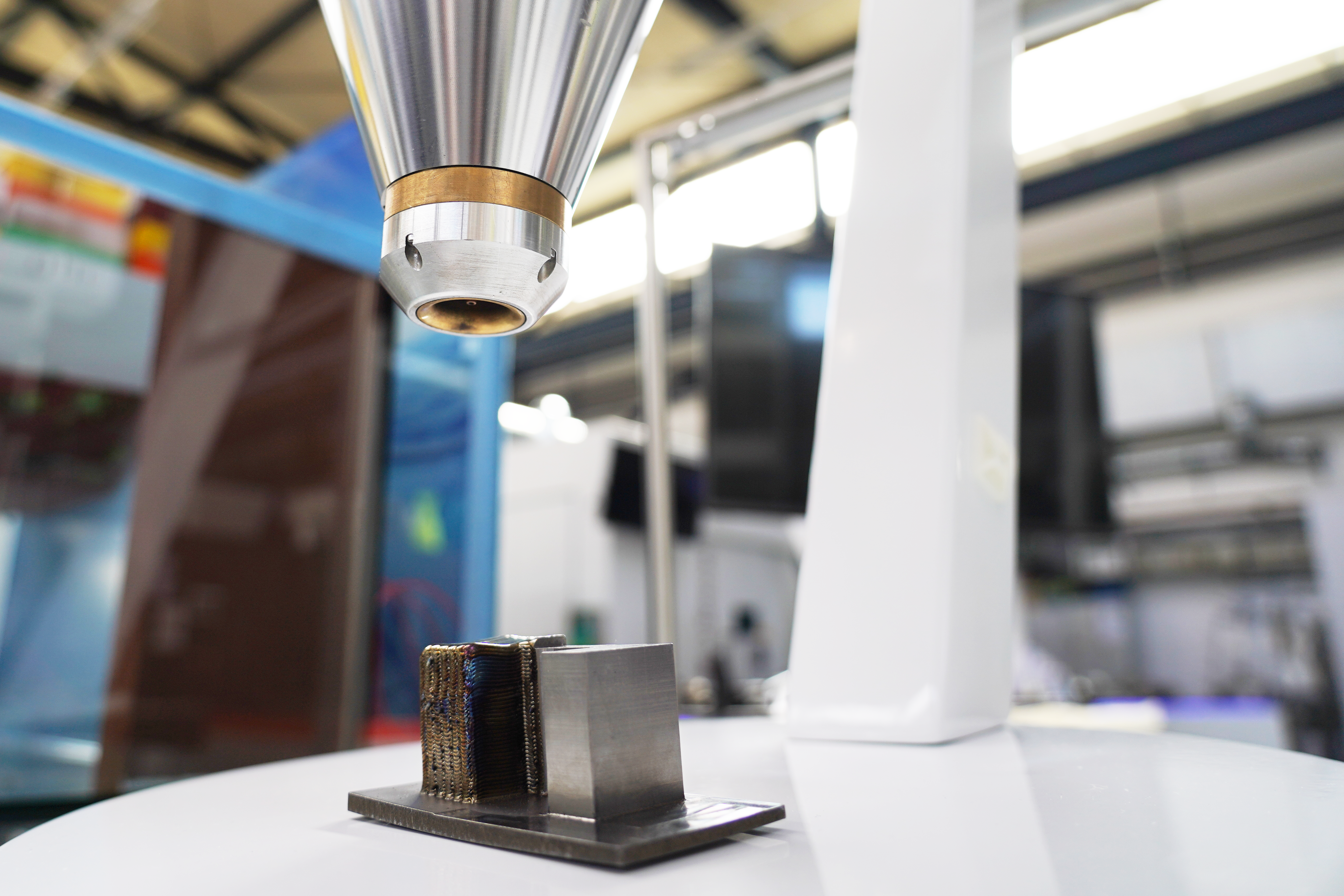

Coaxial laser processing head for additive manufacturing

At the LZH we develop complete custom solutions for laser material processing. This includes both the processes and the associated equipment and system technology: With our customized laser processing heads, we bring innovative applications into production.

The coaxial multi-diode laser processing head developed at the LZH for laser wire deposition welding can process customized components regardless of the welding direction. Our laser processing head saves material through additive manufacturing and, depending on the application, can also save energy as well as extend the lifetime of heavily stressed components.

At a glance

• Objective: Multidirectional laser cladding even on curved surfaces

• Possible beam sources: FKL from 950 nm - 1100 nm

• Power: up to 3 kW in 4 partial beams

• Hot wire with up to 200 A heating current

• Apperture: 30 mm - 42 mm

• Materials: e.g. steels and titanium alloys as wire with diameters of 0.6 mm - 1.6 mm

• Wire conveyor integration possible

• Various shielding gas nozzles possible, depending on the application

• Adapters for various collimators possible

Receive the link to this site per mail

Would you like to access this information again later? Please submit your email-adress here. You will receive a one time mail with the link to the information. . If you would like to stay up-to-date to news from the LZH, you find the opportunity to subscribe to our newsletter or our social media channels in the mail.