Laser against biofouling: Eco-friendly underwater cleaning of ship hulls

Biofouling is the growth of algae, mussels, and other marine organisms on the hull of a ship. The fouling increases the flow resistance of the ship - and thus increases fuel consumption and CO2 emissions. Mechanical cleaning of the fouling can damage the hull coating. In addition, the fouling must be extracted if organisms or even parts of the ship's coating are not to get into the water. Scientists from the LZH, together with Laserline GmbH and the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research IFAM, have now developed an environmentally friendly and efficient solution to the problem of biofouling.

Eco-friendly cleaning with the laser underwater

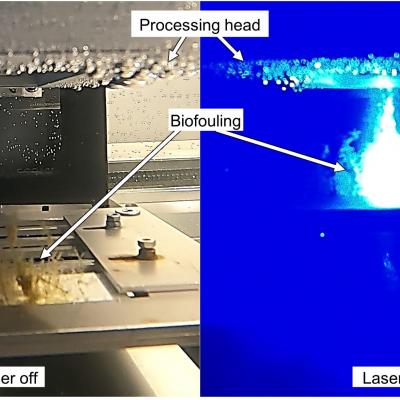

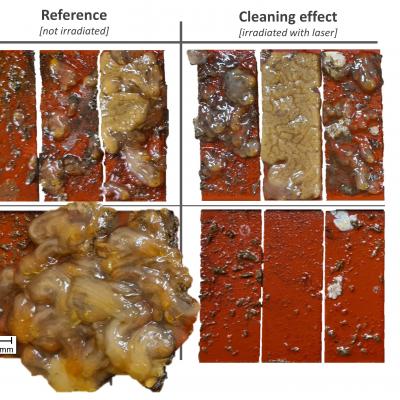

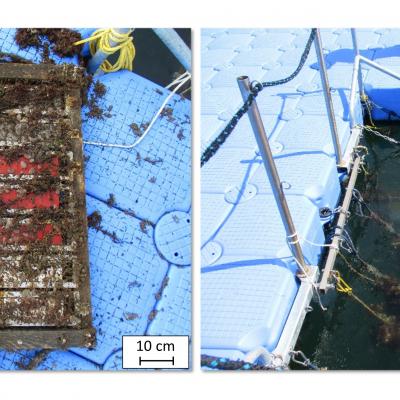

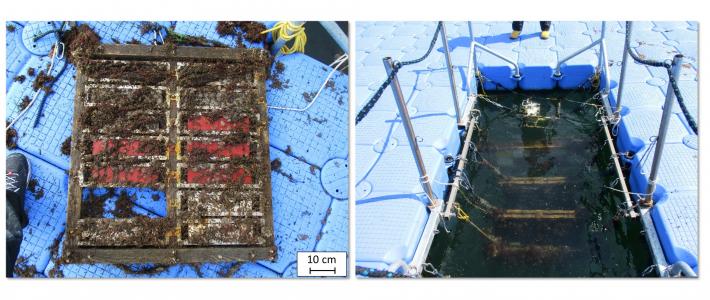

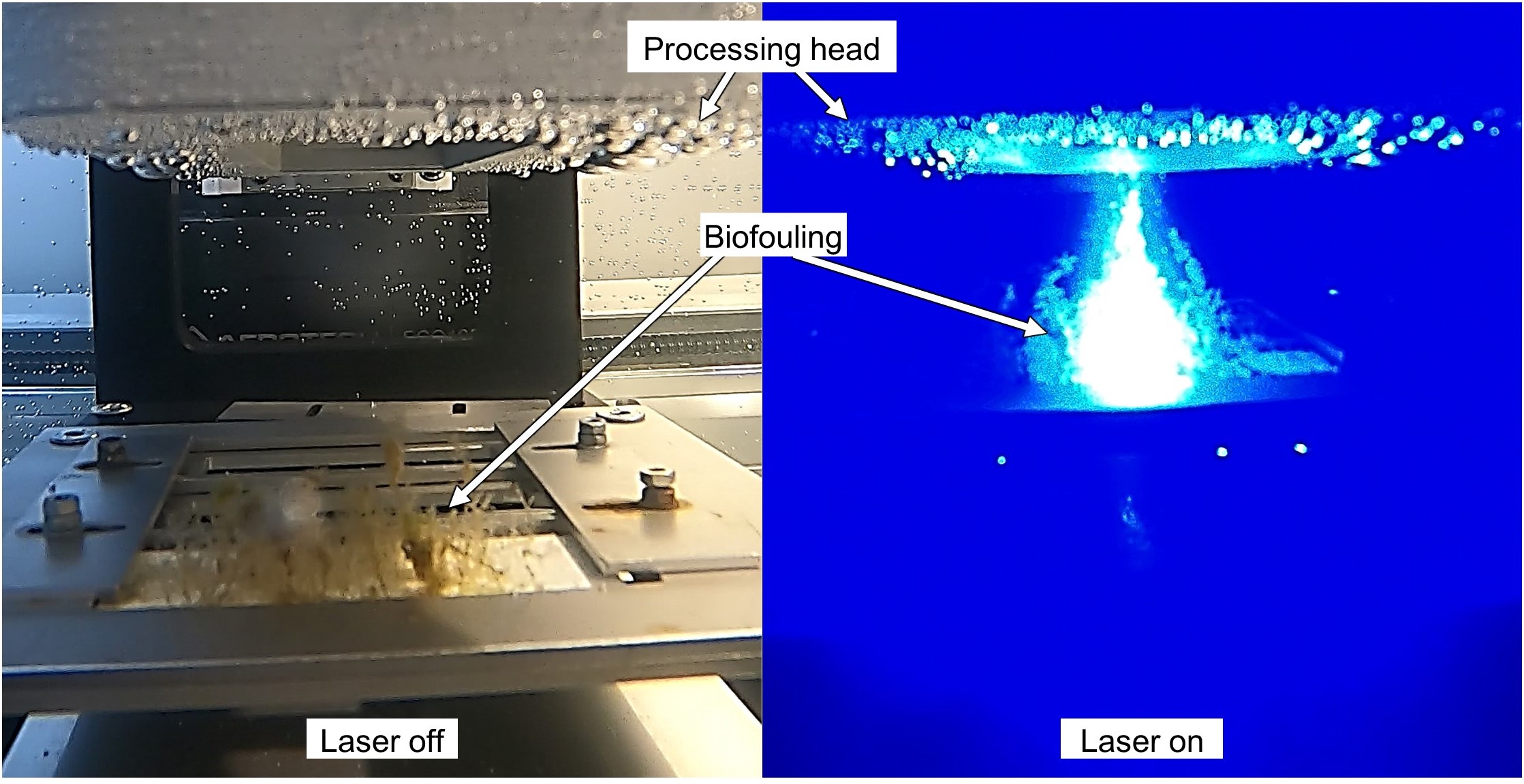

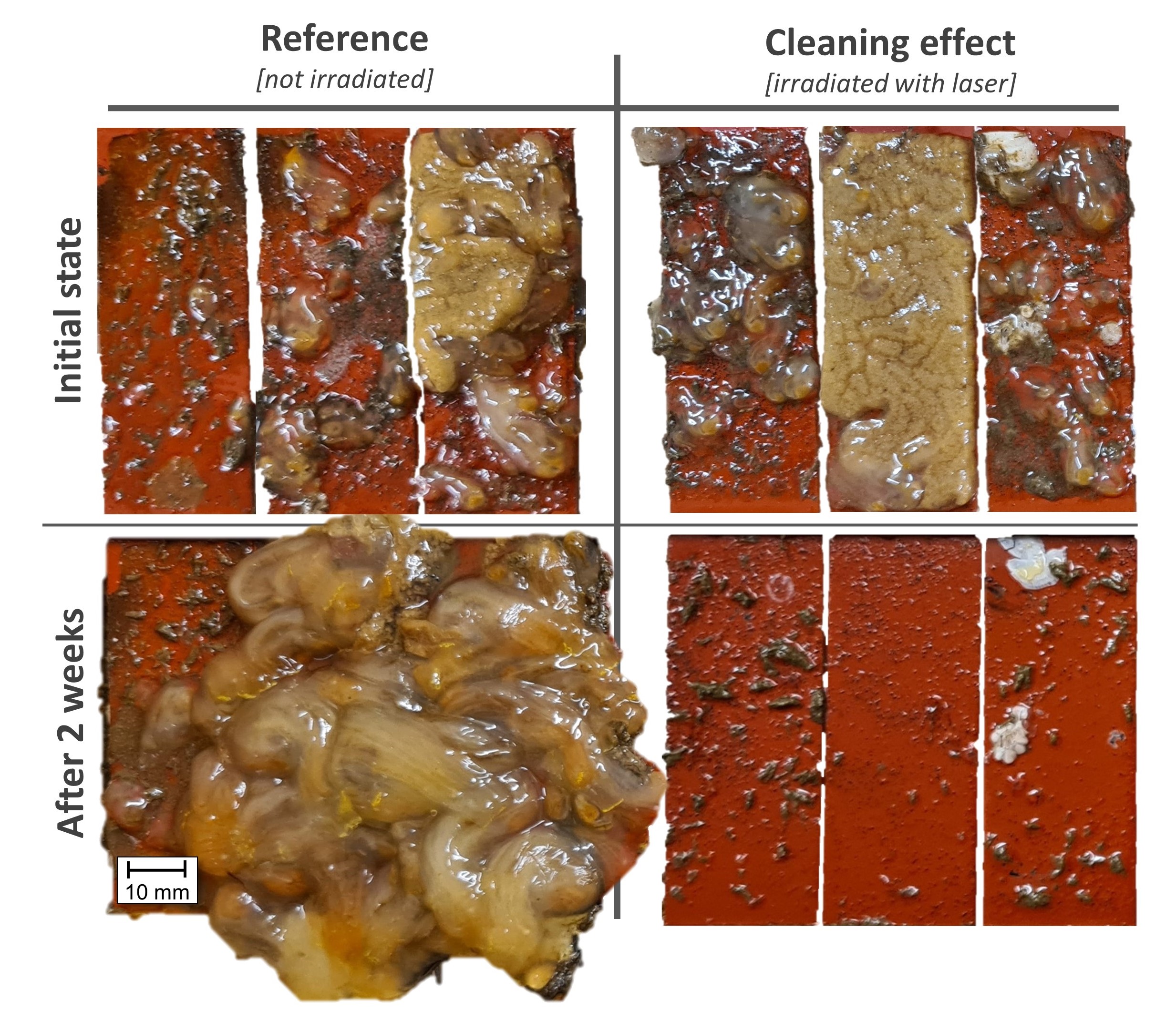

Laser radiation can be used to lethally damage marine fouling underwater without damaging the underlying coating of the ship's hull. The LZH scientists have developed a process in which the cells of the fouling are damaged by laser radiation in such a way that the fouling dies and is then simply washed away by the water after some time.

The researchers conducted their investigations in the south harbor of the island of Helgoland. There, they irradiated fouling samples with the laser, then returned them to the North Sea and checked them after two to four weeks. "We were able to achieve a clear, time-delayed cleaning effect," says underwater technology expert Dr.-Ing. Benjamin Emde from the LZH. "With simulated currents, as would be added in real life with a moving ship, the cleaning effect is further enhanced."

Reducing emissions and avoiding species displacement

Biofouling is not only a problem for reasons of fuel consumption as well as emissions. The fouling can lead to the introduction and spread of non-native species in foreign ecosystems. "Species displacement is a major risk of biofouling," Emde says. If a ship introduces foreign organisms into an ecosystem through hull fouling, it can severely disrupt the ecosystem. In practice, this leads to ships being banned from docking in foreign ports, as has happened again recently with cruise ships, for example. Here, as well, cleaning with the laser is a good alternative to mechanical methods: Because the introduced biomass is lethally damaged during laser cleaning, it is no longer dangerous for foreign ecosystems afterward.

About FoulLa

The project "Fouling removal of maritime surfaces using laser radiation underwater - FoulLas" was carried out by the Laserline GmbH, the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM and the Laser Zentrum Hannover e.V. (LZH). The project was funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK) under the funding code 03SX489 by the project coordinator Jülich.

Laser Zentrum Hannover e.V. (LZH)

Als unabhängiges gemeinnütziges Forschungsinstitut steht das Laser Zentrum Hannover e.V. (LZH) für innovative Forschung, Entwicklung und Beratung. Das durch das Niedersächsische Ministerium für Wirtschaft, Arbeit, Verkehr und Digitalisierung geförderte LZH widmet sich der selbstlosen Förderung der angewandten Forschung auf dem Gebiet der Photonik und Lasertechnologie. 1986 gegründet arbeiten inzwischen fast 200 Mitarbeiterinnen und Mitarbeiter am LZH.

Das LZH bietet mit seinen Anwendungen der smarten Photonik Lösungen zu gegenwärtigen und zukünftigen Herausforderungen. Dabei arbeiten Naturwissenschaftler:innen und Ingenieur:innen interdisziplinär zusammen entlang der Prozesskette: von der Komponentenentwicklung für spezifische Lasersysteme oder für Quantentechnologien bis hin zu Prozessentwicklungen für die unterschiedlichsten Laseranwendungen, zum Beispiel für die Medizin- und Agrartechnik oder für den Leichtbau im Automobilsektor. 18 erfolgreiche Ausgründungen sind bis heute aus dem LZH hervorgegangen. Das LZH schafft so einen starken Transfer zwischen grundlagenorientierter Wissenschaft, anwendungsnaher Forschung und Industrie – und nutzt Licht für Innovation.