Technologies for Tomorrow: LZH at the LASER World of PHOTONICS 2025

Our focus: robust laser systems for satellite communication, large-format additive manufacturing, laser-based optimizations for the hydrogen economy, precise characterization of optical components, and the integration of artificial intelligence into photonics.

Precise characterization and ultrafast pulse processing for highest demands

Reliability starts with detail: LZH showcases a stand for custom characterization of optical components. By measuring the laser-induced damage threshold (LIDT), LZH precisely determines the load capacity of optics up to 300 mm in diameter. The insights gained allow LZH to develop new high-load optical components for use in high-power lasers, such as those developed for fusion research. In the field of ultrafast pulse processing, LZH presents a range of methods for structuring, modifying, and functionalizing materials and thin films with the highest precision. These technologies open up diverse applications in integrated sensor technology, optics, and microelectronics.

Laser and integrated photonics for satellite and quantum communication

For secure and fast satellite communication, LZH develops customized energy-efficient fiber amplifier systems based on self-made fiber components. Additionally, LZH develops and manufactures custom laser systems for a variety of industrial and research applications. LZH also showcases its expertise in producing particularly compact and powerful photonic systems for quantum key exchange - the technological foundation for tap-proof communication.

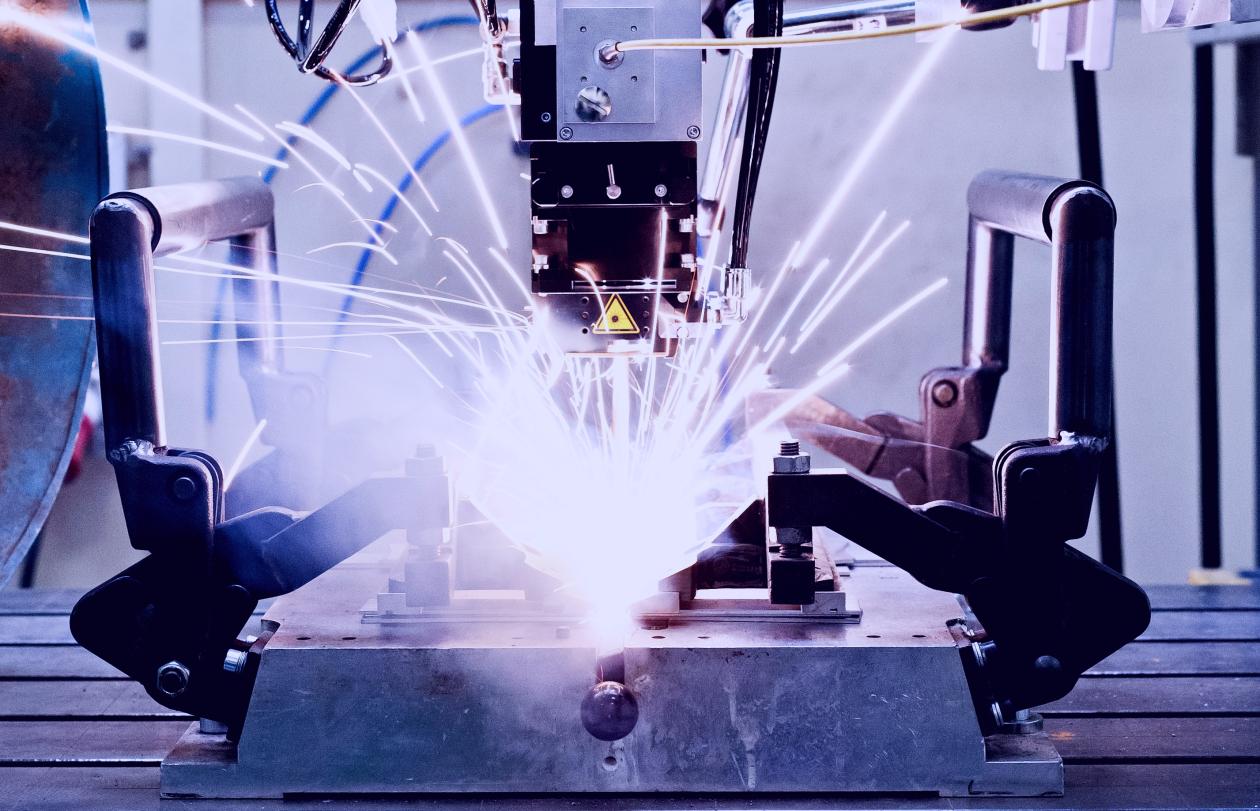

Large-format additive manufacturing through laser deposition welding

In additive manufacturing, LZH demonstrates how large-format and functionally integrated metal components can be implemented using laser-based deposition welding methods (DED-LB/M) - for example, for ship, machine, or plant engineering. Intelligent process monitoring, innovative robot software, and specially developed system technology enable precise and reproducible results from steel to titanium.

Processes for maritime applications and hydrogen production

A special highlight at the booth: a demonstrator for biofouling removal on ship hulls - resource-efficient and sustainable. Visitors can also learn more about innovative methods for reliably joining steel and aluminum, particularly relevant for shipbuilding, as well as processes for efficient electrolysis and hydrogen combustion.

By strategically integrating artificial intelligence into LZH processes, the institute unlocks new opportunities for process optimization and quality assurance.

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. Supported by the Lower Saxony Ministry of Economics, Transport and Building, the LZH is dedicated to selflessly promoting applied research in the field of photonics and laser technology. Founded in 1986, almost 200 employees are now working at the LZH.

The LZH offers solutions to current and future challenges with its smart photonics. Along the process chain, natural scientists and engineers work interdisciplinary together: from component development for specific laser systems or for quantum technologies to process developments for a wide variety of laser applications, for example for medical and agricultural technology or lightweight construction in the automotive sector. 17 successful spin-offs have emerged from the LZH to date. Thus, the LZH creates a strong transfer between fundamental science, application-oriented research, and industry - and uses light for innovation.