OKuDaLas – Surface Conditioning of Copper Materials to Stabilize Continuous Wave Laser Microwelding

Surface Conditioning of Copper Materials to Stabilize Continuous Wave Laser Microwelding

"OKuDaLas"

The IGF Project 18.335 N of the research association DVS German Welding Society was financed by the German Federation of Industrial Research Association „Otto von Guericke“ (AIF) within the framework of the support program of the Cooperative Industrial Research (IGF), German Federal Ministry of Economics and Technology (BMWi) based on a decision of the German Bundestag.

Motivation:

Within the improvement of essential products of the German industry also the production techniques need to be further developed according to the given general economic conditions. In the framework of this project and based on the newest research results, the process reliability of welding copper and copper alloys using laser radiation should be further developed for competitive industrial applications.

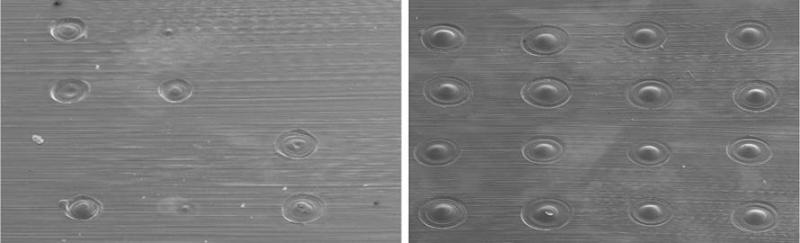

Illustration 1: Only pulsed IR radiation (left), combination of green/IR pulsed (right)

The primary goal of this project is to develop an economical process for industrial applications aiming at increasing the stability of laser welding of the specified materials, and at the same time increasing the performance, as compared to processes already in use. The concrete reason for implementing this goal is the advantages already present in conditioning workpieces using short, frequency converted 532 nm laser pulses (see illustration 1) for pulsed laser welding applications of copper and copper alloys using infrared laser radiation. In the framework of this project, investigations will be carried out on how and to which extent the advantages of the above-mentioned conditioning can be transferred to welding with continuous wave infrared laser radiation.

On the one hand increasing the coupling in of infrared laser radiation after conditioning promise improved process stability.

On the other hand, the process time for welding when using infrared beam sources, which are already present in small and medium-sized organizations, can be substantially shortened. At the same time, this approach, which in industrial implementation involves only retrofitting the existing equipment, presents a considerably more economical alternative to new acquisitions or the use of a continuous wave source for frequency doubled green laser radiation.

Currently:

An OKuDaLas Kick-Off Meeting took place at the industrial project partners Wieland-Werke AG in Ulm (see illustration 2). Inter alia the types of alloys and the material strength of the samples have been defined. Also discussed was the use of possible laser sources.

Illustration 2: PbA-Kickoff meeting in Ulm November 18, 2014

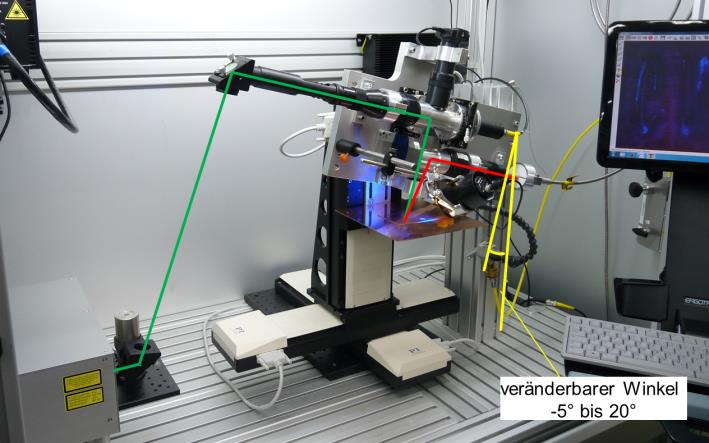

Illustration 3: Experimental setup

Current Research Results

In the first brief trials, areas on copper samples made of different compositions were hatched using a laser system (wavelength λ = 532 nm) already available at the research institute and using different parameters. The experimental setup is shown in illustration 3.

Subsequently, blind seams were applied using a cw laser (λ = 1070 nm), see illustration 4. It could be shown that the coupling in probability of IR laser radiation was improved after the surface was conditioned, and that it increases with higher pulse energy of the conditioning beam. Further, these trials show that a cw output of 140 Watts for the welding process of the specified copper samples is not sufficient.

Illustration 4: IR coupling behavior for increasing pulse energy

Committee Accompanying the Project (PbA):

The project partners involved in the committee accompanying the project cover all relevant thematic areas and fields, in order to efficiently achieve the goals mentioned above. Apart from the Laser Zentrum Hannover e.V. (LZH), the following enterprises are represented in the committee accompanying the project:

- arteos GmbH

- BPE International GmbH

- DirectPhotonics Industries GmbH

- Hesse GmbH

- IPG Laser GmbH

- Laser on demand GmbH

- LMB Laser-Materialbearbeitungs GmbH

- Miyachi Europe GmbH

- neoLASE GmbH

- Nexans Deutschland GmbH

- SCANLAB AG

- Sill Optics GmbH & Co. KG

- Wieland-Werke AG

Contact:

Laser Zentrum Hannover e.V.

Dr.-Ing. SFI Jörg Hermsdorf

Head of the Machines and Controls Group

Hollerithallee 8

D-30419 Hannover

Germany

Tel.: +49 511 2788-472

E-mail: j.hermsdorf@lzh.de