Repairing pixel errors in AMOLED displays

Pixel errors in AMOLED displays cause high reject rates. To date, there are no repair processes for these flexible, high-resolution displays. The Laser Zentrum Hannover e.V. (LZH) and three partners are now aiming to change this.

The reason for errors in AMOLED displays are mostly short circuits or missing conductors. So far, repair processes for the required resolutions do not exist. Therefore, either the customer receives a defect display or it is sent to the scrap heap.

Combining additive and subtractive processes

Together with the Neotech AMT GmbH in Nuremberg, a manufacturer of 3D-printed electronics, the equipment manufacturer HPK Inc. in Korea and with the Korea Institute of Machinery & Materials (KIMM), the LZH is working on a machine that combines subtractive and additive processes.

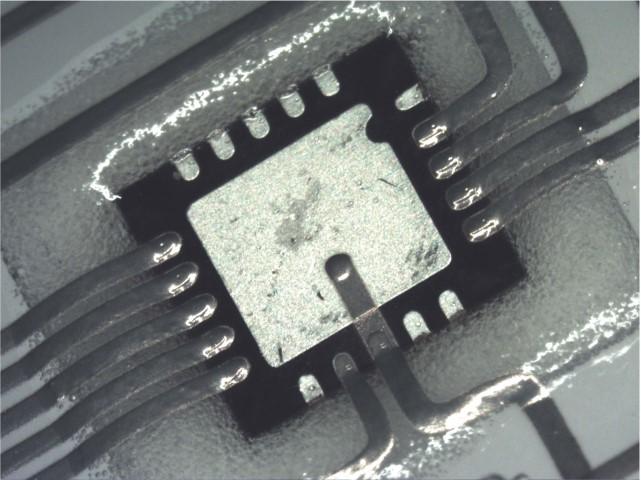

To eliminate the short circuit, the partners want to partly or completely remove the defect contacts with a femtosecond laser. If this is not sufficient, or should there be no conductor at all in the defective area, a new conductor shall be printed by an additive manufacturing process.

Moreover, the process is supposed to create conductive connections between Surface Mount Devices (SMD) on three-dimensional components.

Printed conductors in the micrometer range

To comply with the resolution of the display, the conductors must have a width of about only 1 µm and up to 20 µm length. Printing such conductors with silver nano inks is already possible under lab conditions. However, a process for real-life application has not yet been established. In the coming years, the scientists at the LZH will be working on a processing head and a process for the additive repair of conductors.

The „Replay“ project is supported by the German Federal Ministry of Education and Research (BMBF) within the scope of the Eurostars funding program.