Laser welding process for highly accurate digital measuring gauges

To produce the digital measuring gauge, thin spring plates must be joined in a sandwich combination. This process must be very accurate and reproducible - this is not yet possible with conventional joining methods. Therefore, the Laser Zentrum Hannover e.V. (LZH) is currently working on a laser-based process.

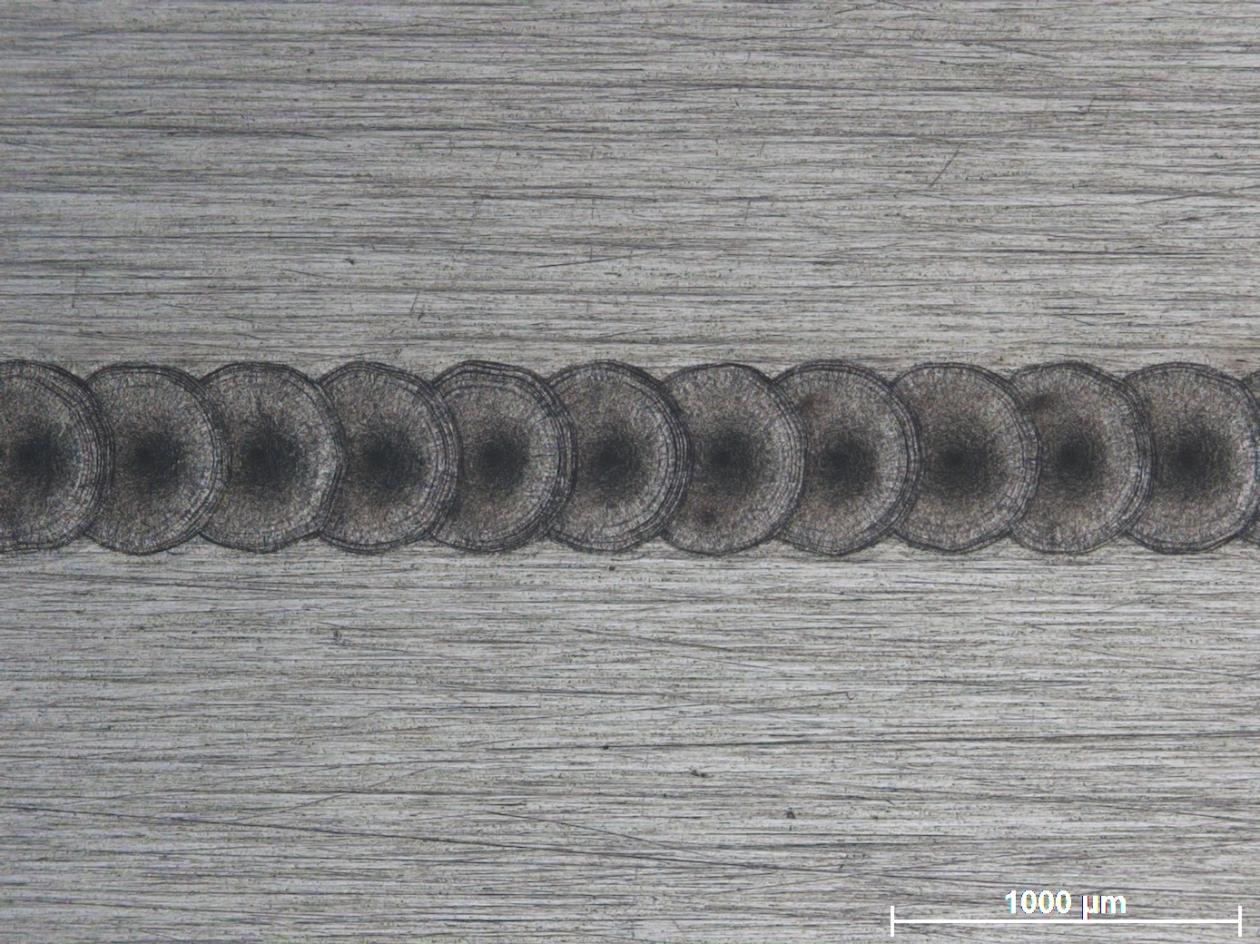

The patented "Digital feeler gauge" by MFP GmbH, Wunstorf, makes it possible to digitally measure gap distances and read out the measured values. The construction of the gauge is based on tenths of a millimeter thin spring plates. These must be joined in such a way that a very narrow cavity is created inside where the sensor electronics are housed.

So far, the gauge cannot be produced with conventional methods and reproducible qualities. The LZH now wants to change this together with the MFP GmbH: The scientists at the LZH are currently developing a laser-based manufacturing process for the production of the digital feeler gauge. This highly complex joining process must meet challenging requirements with regard to accuracy, product quality, process reliability and reproducibility. For example, dimensional accuracy, remaining geometry accuracy and joint quality must not vary. The results will be integrated into a plant demonstrator, which will be developed within the scope of this project.

About "Development series production of the digital feeler gauge"

The project "Development series production of the digital feeler gauge"(ProLaFü) is funded by the NBank with funds from the European Regional Development Fund (ERDF) and from the Lower Saxony State Program Stronger Developed Region (SER) within the framework of the Lower Saxony Innovation Support Program for Research and Development in Enterprises (Grant number: ZW 3-85020391). In addition to the LZH, MFP GmbH, Wunstorf, is involved in the project.